We may garner revenue from the mathematical product uncommitted on this page and take part in affiliate programs . Learn More ›

The future has arrived with 3D printing , and it ’s not just for creating cunning toy . Builders now are constructing in full liveable homes with the power of this newspaper clipping - boundary applied science , both in the United States and abroad .

Although the 3D - printed caparison market is in its babyhood , it is expected to smash in the come yr due to advancement in technology , increase interest in sustainable construction practice session , and a need for affordable lodging . The three-D - printed housing grocery was valued at $ 36.8 million in 2022 and is expected to grow to more than $ 1 billion by 2030 , a growth rate of 61.5 percent during the forecast period ( 2023 - 2030 ) .

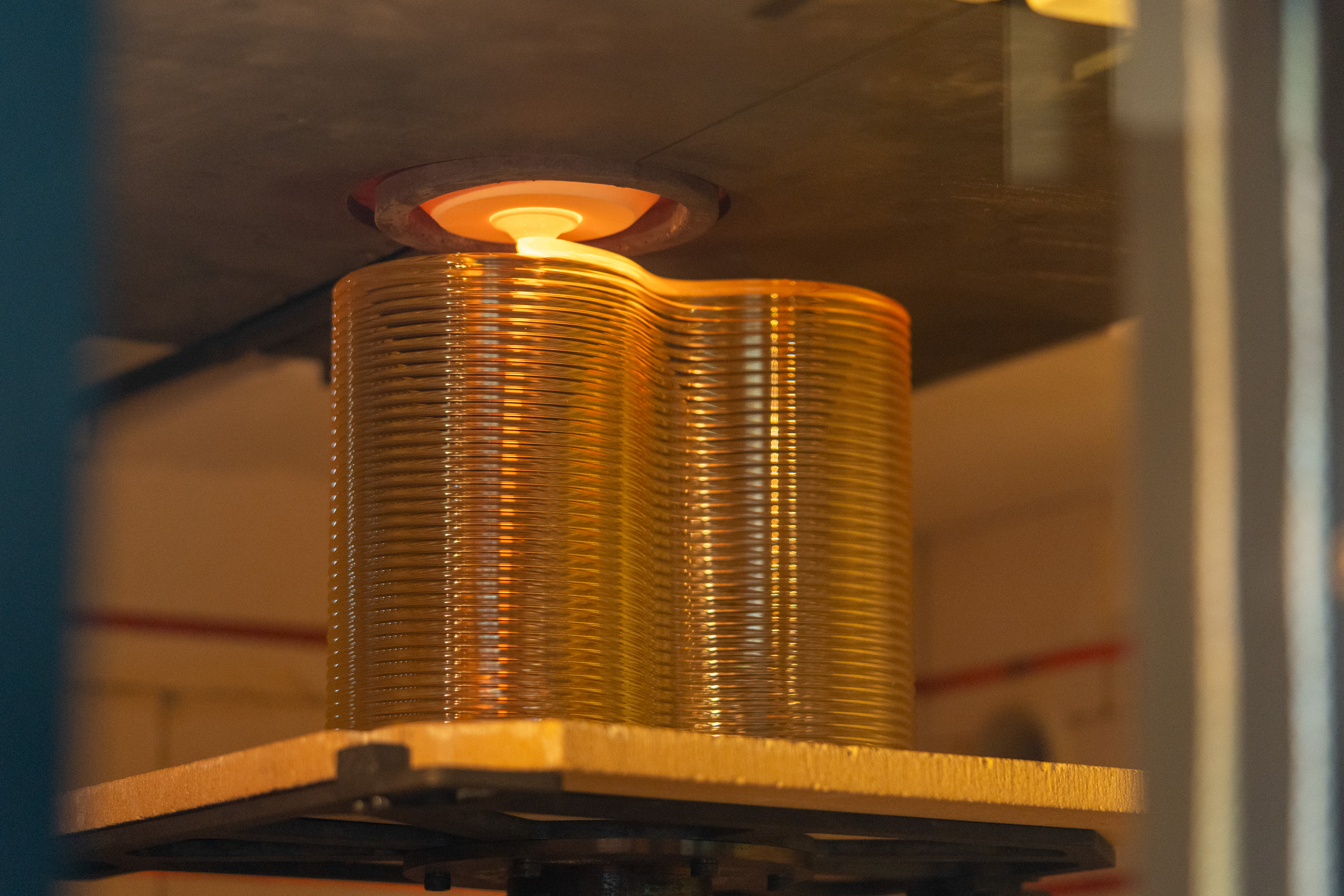

Photo: Ethan Townsend via Massachusetts Institute of Technology.

While most 3-D - printed homes are presently being construct using concrete or charge card , engineers at the Massachusetts Institute of Technology ( MIT ) have just develop a way to 3D print building blocks from recycled glass . This discovery could open up the 3D - printed housing market to Modern opportunities as demand increases .

What the Engineers Discovered

Kaitlyn Becker , helper professor of mechanically skillful engineering at MIT , and Michael Stern , a former MIT graduate student and researcher in both MIT ’s Media Lab and Lincoln Laboratory , who is also the founder and director of 3D - printed glass manufacturer Evenline , have develop sturdy 3-D - printed field glass blocks to be used in building construction undertaking .

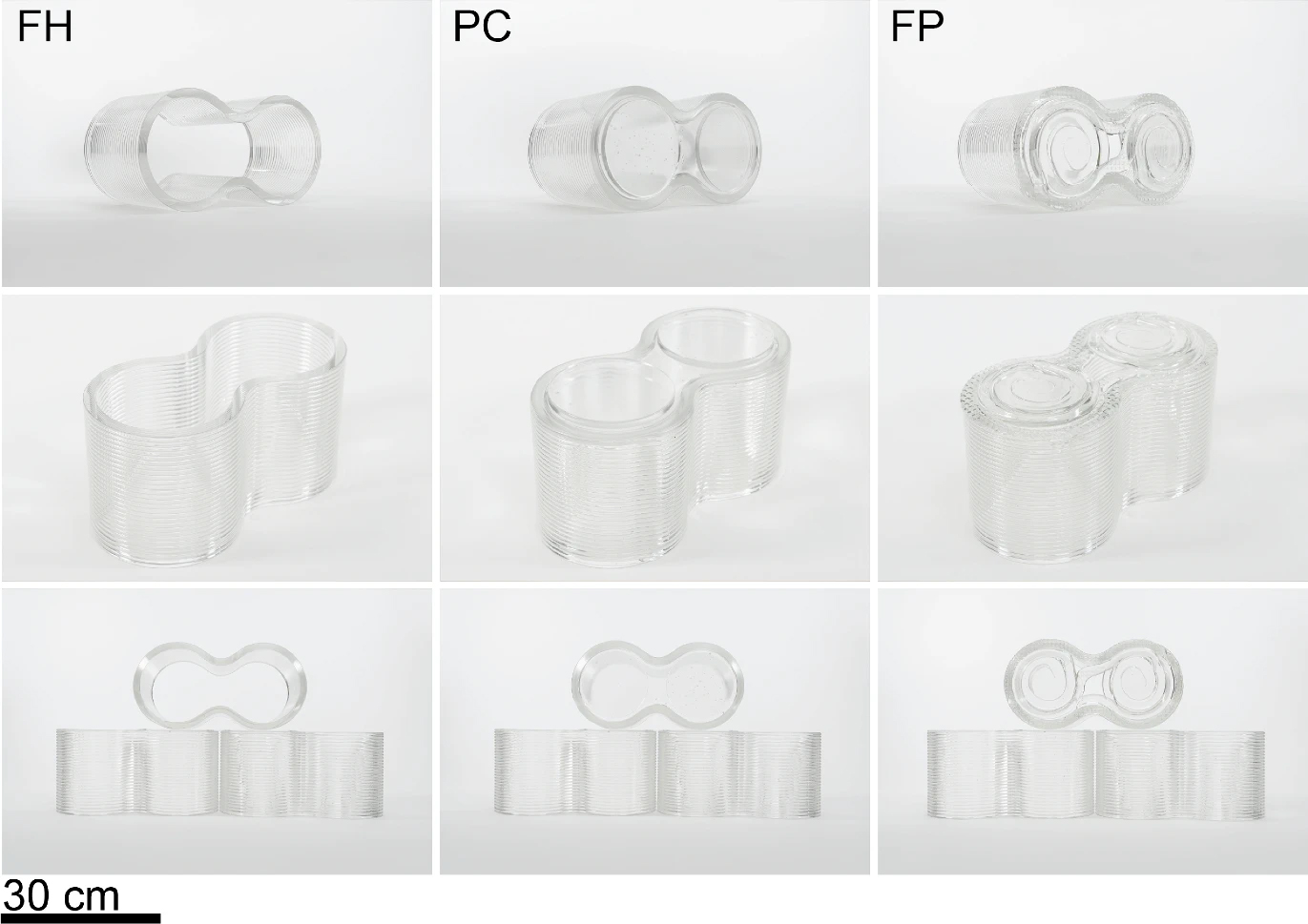

Detailing their glass brick design enquiry and development in a study appearing in the journalGlass Structures and Engineering , the engineer make a new kind of reconfigurable masonry made from three-D - impress recycled methamphetamine hydrochloride . These interlocking , multilayered glass brick have two rotund nog and connect like LEGOs do . They can be colligate together and stack to build body structure just like regular brick . The engineers choose to design the brick in a figure-8 shape , so they could be used to build curved walls .

The glass blocks are printed using Evenline ’s usage 3D glass printing technology . It connect with a furnace to mellow out crushed crank bottleful into a molten , printable fabric that the printer deposits in superimposed patterns . For their prototype , the squad used soda - lime glass , which is unwashed in glassblowing studios . An additional material is placed between the brick to prevent scratches or fissure between glass Earth’s surface .

Photo: Ethan Townsend via Massachusetts Institute of Technology.

This Invention Tackles Environmental Challenges

The construction industriousness currently has a heavy environmental footprint . manufacture building material make up about15 percentof global greenhouse gas emissions , and the construction and demolition industry send more than 145 million tons of waste to landfill every year , harmonize to theEnvironmental Protection Agency .

With these environmental challenges in mind , the MIT engineers wanted to find a more sustainable approach . They turn to orbitual construction , which direct to reuse and repurpose a building ’s materials whenever potential . By creating glass blocks made from recycled spyglass that can be reused over and over again , they are minimize the impact from manufacturing newfangled materials . This , in crook , reduces the construction diligence ’s incarnate carbon , which refer to the nursery gas emissions tie in with all the processes throughout a building ’s construction , from manufacturing to demolition .

The best part of glass is that it can be recycled endlessly , as long as it is n’t foul . That think these 3D - printed trash blocks can be disassembled at the closing of a building ’s lifetime and then repurposed many times over in newfangled buildings . It can even be put back in the 3D printer to make completely newfangled shape .

Photo: Ethan Townsend via Massachusetts Institute of Technology.

How 3D Printing With Glass Compares to Concrete

The most vulgar material used for three-D - print houses is presently concrete . It is widely useable , affordable , and able to be organise into complex shape and structures necessary for construction projects .

The MIT team is cognizant of this , so they made sure to test their 3D - print glass mental block to see how they compare to concrete . After test the glass blocks using an industrial hydraulic wardrobe that squeezed the bricks until they begin to fracture , they plant that those made mostly from printed trash with separate interlocking features on the bottom were the strongest and oblige up to the highest amount of pressure . In fact , the superimposed blocks could withstand pressures similar to those that concrete blocks withstand .

These are prognosticate results , and the team at MIT hopes that these glass blocks can soon be used as an choice , or improver to , concrete andplastic to make 3D - printed theater .

What the Future Holds

The MIT researchers plan to descale up their design to build with child social structure , such as a pavilion . Between the newfangled product they are bringing to the forefront and the potential difference for more demand and increase in the 3D - printed trapping market place , this is a sector to keep an eye on . We may soon see three-D - printed houses made from recycled glass brick .

For now , you could find 3-D - print rest home in a few locating . A trapping development in Georgetown , Texas , has 100 3-D - printed homes , and there are 10 houses so far in Austin . Habitat for Humanity help build homesin Williamsburg , Virginia , and Tempe , Arizona , using the technology , and the company they partner with plans to construct additional 3D - print residences in Arkansas , California , Iowa , North Carolina , North Dakota , and Pennsylvania .

Everything You take for a Lush and Healthy Lawn

Keeping your Mary Jane fleeceable and your plants prosper does n’t just take a green pollex — it start up with the right tools and supplies .