We may earn taxation from the production usable on this pageboy and participate in affiliate programs . see More ›

When learning how to weld , it ’s important to researchthe best welderfor your needs . Another essential element of this science is understand the unlike character of welds , as each has an impact on the strength and durability of the ruined work .

There can be disarray among the type of Weld , and the joints used . Not all weld are suitable for all joint . Some have very specific U.S. . surface Weld , for example , are n’t used for joining two piece of metal . The following provides more point to these important pointedness , giving beginner welders , in peculiar , the entropy they need for a wide variety of welding undertaking .

Photo: istockphoto.com

Types of Welds

In commercial post , a job shroud will often includestandardized dyer’s rocket symbolsthat indicate the type of weld to be used . These carry far more detail than is necessary for the tiro , and the following information is often sufficient forDIY welding .

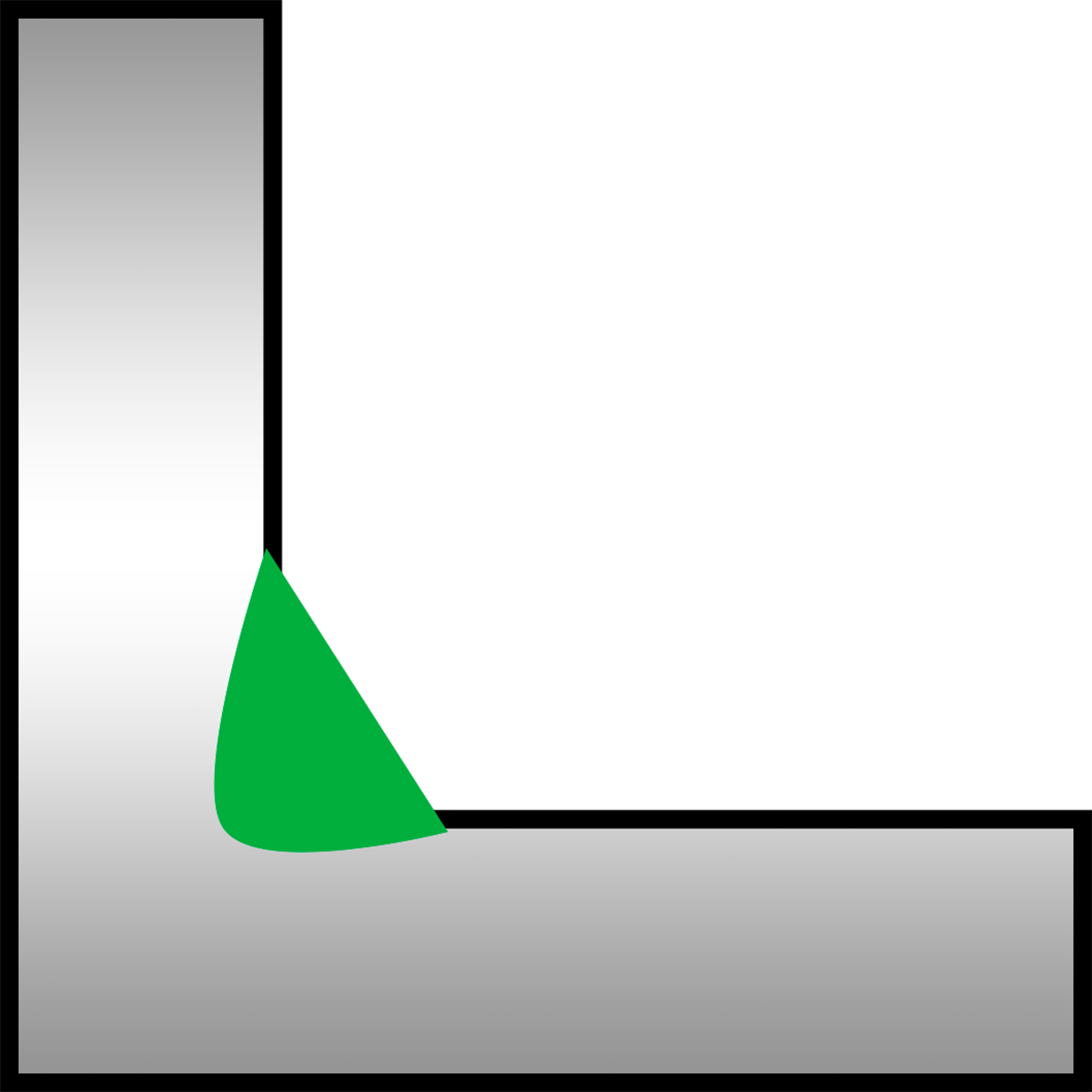

1. Fillet Weld

The fillet weld is undoubtedly the most vulgar type of Theodore Dwight Weld . It is relatively easygoing for beginners to master with their firstMIG welder , and has the strength and versatility for a whole boniface of professional applications . It can be used for many types of joints , whether the alloy is at an slant , imbrication , or when the end of a cylinder postulate to be welded to a vapid sheet .

fabric to be joined require little readiness , and strong welds can be achieved quick .

Best For : All common welding tasks except butt joint .

Illustration: BobVila.com

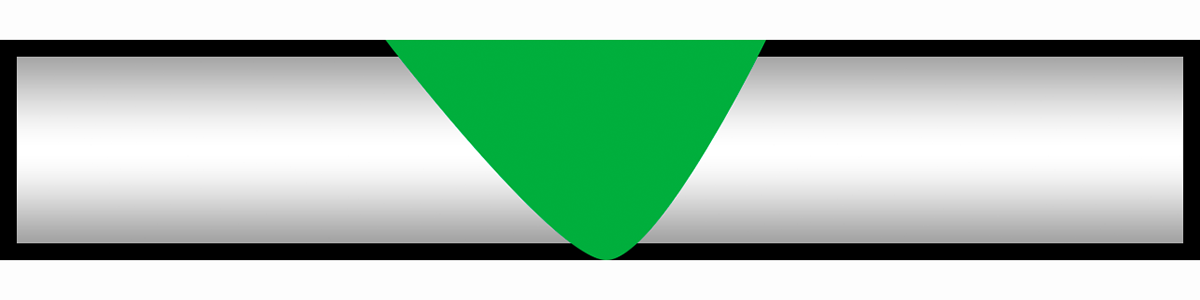

2. Groove Weld

At first glimpse a groove weld looks like to a fillet weld . They are mold in much the same direction , and have similar applications . However , the channel dyer’s rocket come home further into the metal . This additional thickness makes it the unattackable type of weld in most situations .

The drawback is that a groove is expect for the liquified alloy to fill . Thus a chamfer , v- , or u - condition motive to be formed between the two pieces to be get together ( some groove dyer’s rocket are also called bevel weld ) . This increases preparation time .

Best For : Any weld where maximum strength is required .

Illustration: BobVila.com

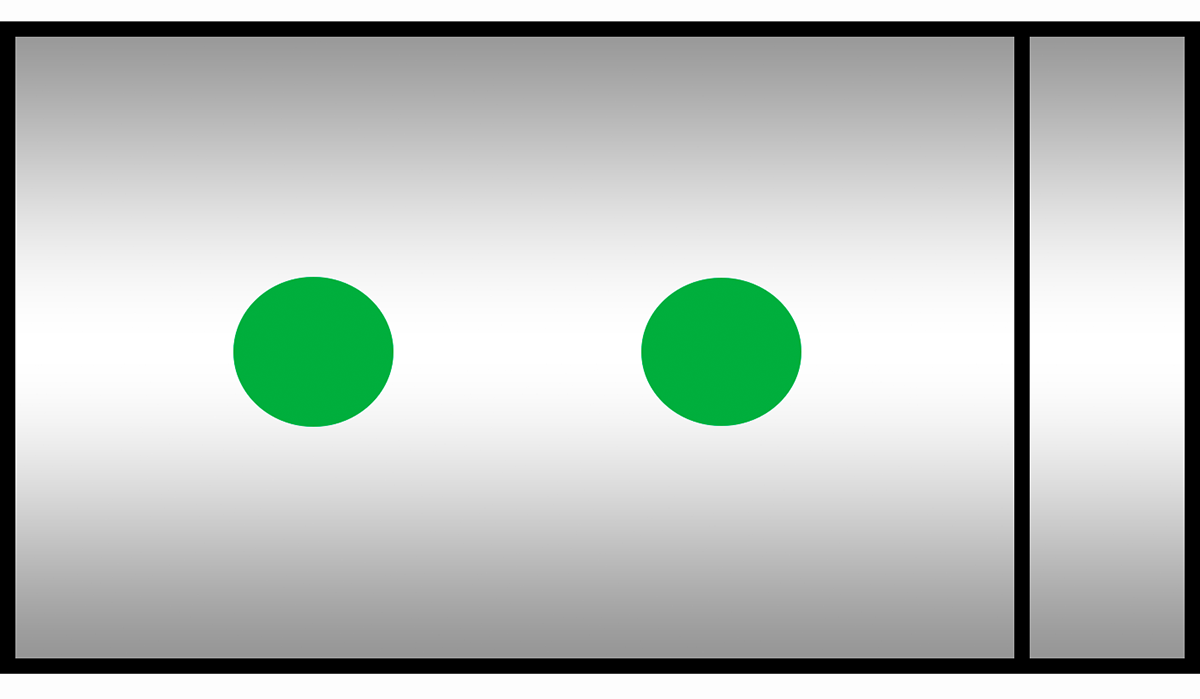

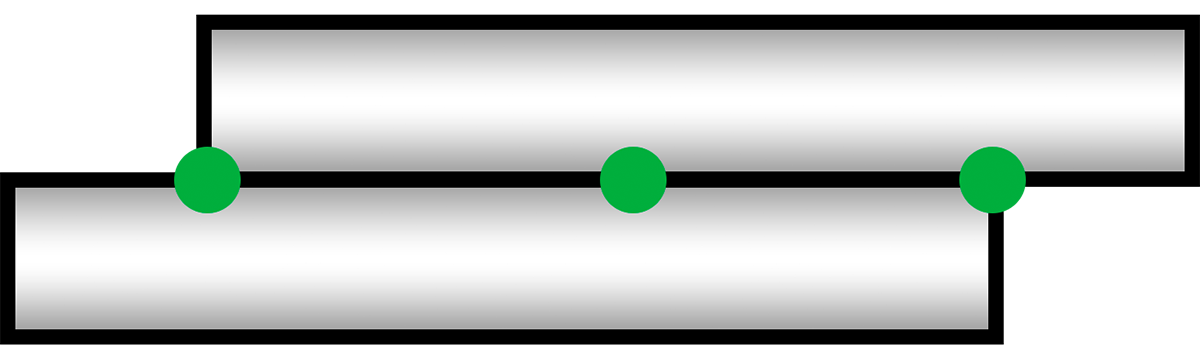

3. Plug Weld

A hack weld is used to bring together two overlap pieces of metal . It is often used when a spot welder ( see below ) does n’t have sufficient ambit , or lacks the power to get through thicker components . A distinctive practical app is for recreate vehicle floor pans .

One or more holes are bore or cut in the top piece , which is then clamped over the second while the holes are fill with weld cloth , thus creating a joint .

Best For : Large or duncish overlap theatrical role that are not open to major loads .

Illustration: BobVila.com

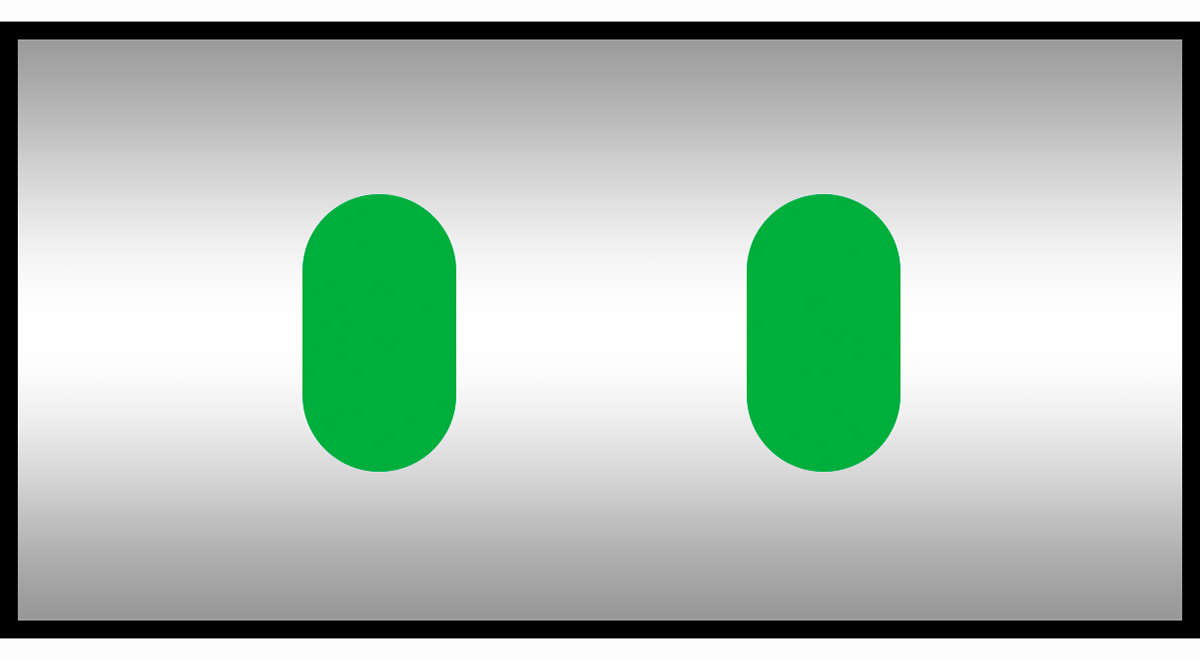

4. Slot Weld

A slot weld is basically an stretch plug weld . Instead of a simple hole ( or holes ) , a expansion slot is formed in the top surface . This slot can either be inclose or assailable all over . The main advantage that a slot Theodore Dwight Weld offers is increase weld contact area , and hence nifty strength . However , it does require significantly more weld material .

well For : When greater military strength is call for than provided by spot or plug Theodore Dwight Weld .

5. Surfacing Weld

As antecedently mentioned , surface welding is not used to join two pieces of metal together , but rather to deposit Reseda luteola material onto a surface . This may be done to fill spread and holes ( replacing metal lost through rust for example ) , or to inspissate , and thus reenforce exist components .

One or more runs of weld ( call beads ) are deposit , which may then be grind back to provide a smooth surface for house painting or plating .

Best For : Repair of damage airfoil . Strengthening .

Illustration: BobVila.com

These first five are the most common welds in oecumenical use . The watch are either more specialize , or are most likely to be found in manufacturing and other production environment .

6. Spot Weld

With smirch welding an electrical current is passed between two points to mellow the metallic element between them . conceive of clamp two sheets of metallic element between your ovolo and forefinger . The process is called resistance welding . It is mostly used for fragile shroud metal , and it is common to see a row of ‘ spot ’ used to stitch two piece together .

Spot welding can be very quick . The welding machines are fend - alone equipment ( either hand - held or storey - standing ) , though attachments are available to set aside topographic point welding with some TIG machines .

Best For : Rapid welding lean sheets that are not subject to major payload .

Illustration: BobVila.com

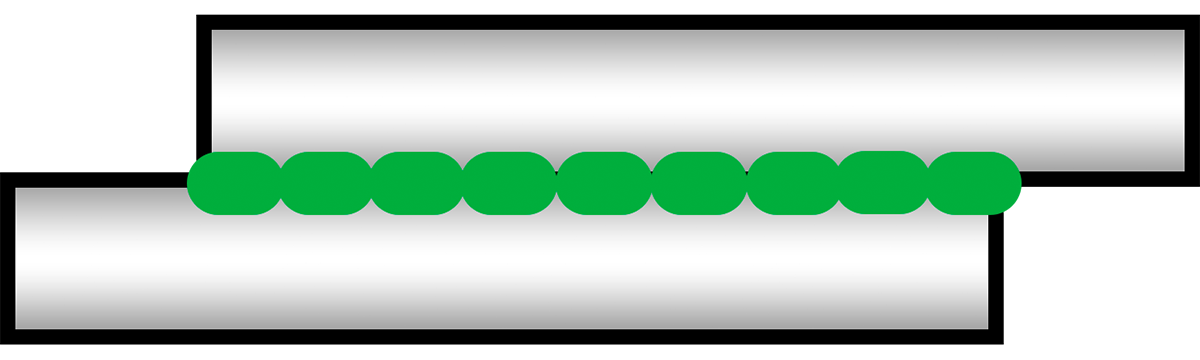

7. Seam Weld

wrinkle Theodore Dwight Weld are also formed using resistance welding . The process is similar to that used for spot welding , but an unploughed business is created . Seam welding is commonly used in the manufacture of tank and drums that involve to hold in gasses or liquid .

A seam weld can also be formed using discharge welding techniques ( MIG or TIG for example ) though grooming is complex , and so seldom used .

Best For : overlap joints on items that need to contain liquid or gasoline .

Illustration: BobVila.com

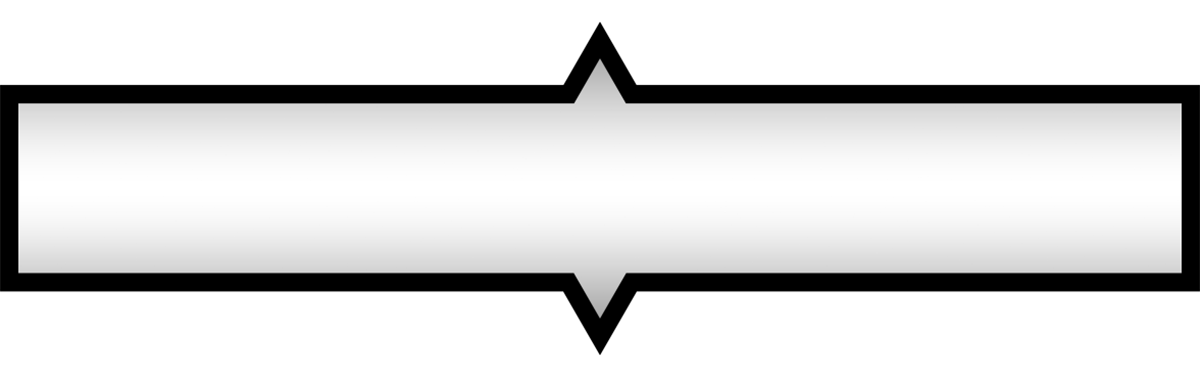

8. Flash Weld

Most type of welding practice some type of filler material , ordinarily from conducting wire or a rod . A newsflash weld does not . It works by heating the end of the metals being joined using the resistance process . Pressure is also applied , which make excess hot metal to be ejected in a series of flashes .

Flash welding is very specialised , most often found on railroad and pipeline grammatical construction .

Best For : join surgical incision of rail or pipework .

Illustration: BobVila.com

9. Upset Weld

disquieted welding is like to dart welding but on modest and light components . It is another form of resistance welding , where the items to be link are clamped together under pressure ( call upsetting ) , and then an electric stream is applied . It is also called resistance butt welding .

distressed dyer’s mignonette are ordinarily modest , and of consistently high caliber . It is normally an automated process used to get together tubular ringing and steel hoops such as gas burners and wheel rims .

intimately For : in high spirits - character welding in production surround .

Illustration: BobVila.com

Types of Welding Joints

Having talk over the different types of Weld , we now need to depend at the common types of welding spliff . This is about how the spell of alloy are aligned with each other . In gild to show how the weld types relate to a special joint , there are relevant example .

Please remark that this information is designed for hobby welder . Those who stand for on welding professionally read the subject in more detail , as each master joint type can have further sport .

mark : Proper rubber precautions are vital with all types of welding . Always wear a high timbre welding helmet and appropriate protective clothing likewelding boots .

Illustration: BobVila.com

This Is the Year for a Kitchen Renovation

Whether you ’re selling or staying , everyone can get something out of a kitchen update . Learn why we view this overhaul the Most Valuable Project of 2025 and how to continue on budget .

Photo: istockphoto.com