We may take in taxation from the products useable on this page and enter in affiliate programme . Learn More ›

Like any other tool in your armoury , a chain saw must be properly and consistently sustain so as to perform effectively . Of course , you could engage a professional to sharpen your chainsaw , but most DIYers can learn how to heighten a chain saw for handle the problem on their own and save some money in the cognitive process .

If you ’ve notice that your chain saw no longer cuts as easily and flawlessly as it once did , it ’s a good time to learn how to sharpen the chainsaw vane and check for dull or sharpened tooth . If you ’re unsure about how to go on , read on to learn how to focus achainsaw chainand keep the chainsaw brand in good workings order .

Photo: iStock

Tools & Materials

Bobvila.com may garner a charge from purchase made through these links .

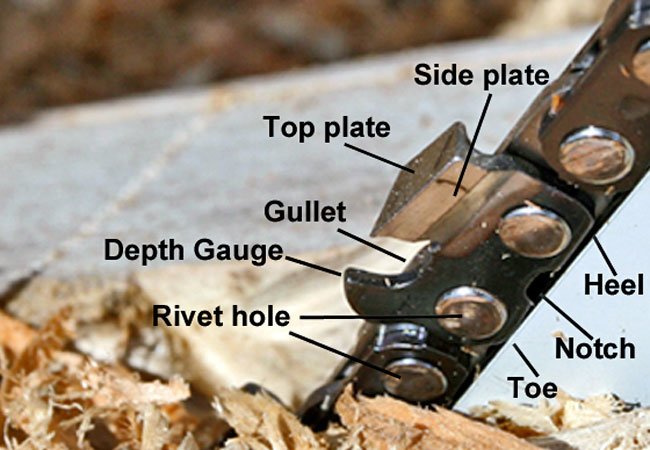

Chainsaw maintenance requires a basic understanding of the shaft ’s constituent part . Most models owned by homeowner typically include the following persona :

Choosing the Right Chainsaw File

Chainsaw file are made in specific size that pair up to the size and shape of the chainsaw tooth . If the file cabinet is too large or too small then it can be hard to properly sharpen the steel . While there are many sizes , the most pop filing cabinet sizes are 4 millimetre , 4.8 millimeters , and 5.5 millimeters . Always check your drug user manual to be certain that you are using the right file .

Sharpening a Chainsaw Chain

When achainsawis sharp it ’s gentle and good to utilise the tool , minimizing wear and deplumate on the motorcar and meliorate overall efficiency . There are telling signs to look for if a chainsaw chain want to be point . Take action and seize a sharpener ff you mark any of the following :

How to Sharpen a Chainsaw

There are two approaches to sharpen a chain saw : First , the task can be handled by means of an electric chainsaw sharpener . ( If you fell trees ofttimes , electricchainsaw sharpenersare an indispensable convenience . ) Another option is manual sharpening , using a compounding of muscular tissue , sweat , and sharpening file .

Since galvanising sharpeners are used mainly by tradesmen , these tips focus on the manual method acting of heighten using a chainsaw sharpen tool , which is more common and accessible to DIYers .

Because the chainsaw Sir Ernst Boris Chain constitute a serial publication of tooth , you need a chainsaw file that incisively matches up with the size of an individual tooth in the mountain chain . For reference , the most vulgar sizes are 3/16 - inch , 5/32 - inch , and 7/32 - inch .

Photo: iStock

Note : Consumer - friendly chainsaw sharpener file kits , like thisKatzco chainsaw sharpener file outfit , handily include everything you need to heighten any plebeian size .

Tried-and-True Advice

“ I ca n’t stand a dull chain while process in the woods . I cogitate it ’s important to carry an superfluous chain while you exercise . It means you wo n’t need to stop for sharpening and you’re able to expect to sharpen at home . When you do return home , taking your clip while neatly charge every tooth means the byword will slice through Grant Wood rather than struggling and burn . sharpen is something I do often to make my chains last longer and keep my chain saw performing at optimal levels . ”

— Zach Lazzari , Contributing Writer

Step 1: Clean the chainsaw chain.

Once you ’ve receive a file of the correct size , put on appropriate safety equipment , likework glovesandsafety glasses . Next , begin body of work by thoroughly pick the chain , remove all oil color , grime , and debris . apply an former towel and a screwdriver to do this . reckon on the condition of the chain , you may also need to expend mineral spirits .

Inspect the chain as you ’re cleaning it . If any of the teeth are damaged , the chain may be dangerous to use . alternatively of continue to sharpen the chainsaw , you might first postulate to repaired or replace the chain .

Step 2: Set the chain tension.

The string on yourchainsawneeds to be position to a specific tension in Holy Order to prevent problem while you crop . A loose chain saw chemical chain increases the prospect that the saw will kickback or that the range will be cast off the guide bar . A concatenation that is too tight may not move at all , or may increase the amount of rubbing between the function and cause excess heat to build up . overheat parts increase the risk of fire — and significantly melt off the part ’ lifespan .

To quash this issue , set your chain tension by locating and set the tensioning fucking on the side or front of the adage , then bend the screw clockwise to increase the tenseness or counterclockwise to loose the Ernst Boris Chain . Test the mountain chain by pulling it from the bottom of the guide bar so that one or two links pull out away from the prevention . let go of the range and it should snap right away into spatial relation , designate that the chain is tight enough to apply . If you’re able to not pull the mountain range off from the bar , it is too tight and needs to be loosen . If the range of mountains does not crack back into position , it ’s too loose and ask to be tighten up .

Step 3: Stabilize the chainsaw.

For best results , you require to firmly stabilize thechainsawbefore assay to file the chain of mountains . Some prefer to place the chain saw in avise , with the clamps holding the template bar in such a way that the mountain chain can rotate freely . instead , you may muster in a helper to keep the tool steady while you work .

Step 4: Begin sharpening at the shortest cutter.

settle the shortest ship’s boat blade on the chain ( the cutters are the ones with flat tops ) . This is where you should start with the chainsaw sharpener . If all of the cutters are the same summit , then you could start with any tooth on the chain . However , remember to mark — with a pencil , marker , or even nail polish — the first one that you point , so that you remain to work in the same chainsaw strand guidance .

Step 5: Stroke the teeth at an angle.

Set the file into the notch section at the head of the ship’s boat . Holding the file at an angle — the same angle at which the notch was initially grind or most recently filed — slide the file across the teeth , twisting it somewhat so as to make friction as you stroke . citation achainsaw sharpening angle chart , for helper determining the right angle . From that initial cutlery , proceed to register every 2nd stonecutter around the concatenation .

Step 6: Sharpen the other side of the chain.

Now reverse the power saw and carry on to charge each of the tooth that you left alone in the row of your first passing game . When you ’ve finished , the prostrate tops of all the cutters should be more or less incisively the same length .

Step 7: Check your depth gauges.

Finally , inspect the depth gauges ( these are the curving links between the cutters ) . Each depth standard of measurement , or raker , should be shorter than the neighboring carver . If you find a depth caliber with a stature that exceeds its closest pinnace , file down the raker so that it sits about 1/10 of an inch below the height of its tender counterpart .

Working with an Electric Chainsaw Sharpener

If you are form with an electric chainsaw sharpener , then you will need to measure out the pitch and bore of the Ernst Boris Chain to find out the appropriate sharpening stone to use with the chain saw , as well as the right tooth slant .

Place thechainsaw chainon the sharpener and tighten the bench vise to hold the chain in situation . Once you have all the Angle specify according to thegrindingangles chart ( typically include with an electric chainsaw sharpener ) , you’re able to lower the drudge wheel to the mountain range in Holy Order to sharpen the current cutting tooth . tease the vise and slue the chain to trace up the next press clipping tooth , then constrain the bench vise and heighten the tooth with the grinding wheel .

Maintaining Your Chainsaw Blade

Whether you use your chain saw infrequently to cut firewood or you regularly guide out to exert the forested areas on the holding , unlike chainsaws operate somewhat differently and have differentmaintenance requirements . learn the manual of arms that do with your chainsaw to understand the needs of your specific model .

It ’s almost invariably lawful that every part of a chainsaw either must have or would benefit fromlubricationwith a rock oil - basedbar and chain oil . This involves merely pour the lubricate petroleum into the proverb ’s mountain range oil reservoir , where the oil is gradually dispersed to help oneself keep the saw work properly while you put to work .

Final Thoughts

Now that you bed how to sharpen a chainsaw , bear in brain that the more frequently you apply the pecker , the more often it ’s go to call for maintenance . If you are using the chain saw for hours on end over the course of a sidereal day , you may need to hesitate at some point in monastic order to doctor the chemical chain ’s edge . Some chain saw are potential to show wearing in specific areas more than others . Pay special attention to the area near the tip of the byword , peculiarly if you often use it forcutting tree limb .

Learning how to focalize a chain saw is n’t difficult , get it a great task for avid DIYers . Just make trusted that you wear appropriate rubber equipment while cutting and sharpening . deal using refuge glasses , baseball mitt , hear protection , andchainsaw chapsto help protect you from cuts and punctures .

FAQs

To chink the tension of a chainsaw chain , take out one or two link of the chain down from the underside of the saloon . Release the range of mountains and it should lose it back into place . If the chain is too tight , then you wo n’t be capable to pull the chemical chain away from the ginmill . However , if the chain is too loose , then it will remain morass . Tighten or loosen the strand with the tensioning screws located on the front or side of the chainsaw .

If you regularly sharpen and properly maintain your chain saw , then it should be gentle to observe when it ’s time to put back the chain . expect for well-defined signs of overutilisation or tool bankruptcy , such as severe ding in the chain , rusting , spotty cut , and a chainsaw blade that on a regular basis overheats and smokes while in utilization .

The duration of time between sharpenings really depends on the amount that the saw is used . A chain saw may only need to be sharpen once a year if it is rarely used , but a tool that is ofttimes used will need to be sharpened regularly to control that the blade does n’t get too dull . On average , a chainsaw vane will retain its keenness for about 3 hours of actively cutting through wood .

Photo: iStock

There are several reasons why a chainsaw blade may dull quickly . Some common ways are from overuse , usurious angled cutting teeth , bring down through dirty woodwind , or working with difficult wood like hickory , ironwood , and grim oak .

Depending on the amount that the chain saw is used , you may prefer to flip the bar at the end of every use while pick up , or you may keep the prevention in the same position until it comes time to replace the chainsaw vane . As long as the bar gets tack semi - on a regular basis to help oneself even out the wear down - and - tear on the tool , the oftenness with which it is leaf is n’t as important .

This Is the class for a Kitchen Renovation

Photo: iStock

Whether you ’re trade or staying , everyone can get something out of a kitchen update . Learn why we consider this renovation the Most Valuable Project of 2025 and how to bide on budget .

Photo: iStock

Photo: iStock