We may earn revenue from the products available on this Thomas Nelson Page and participate in affiliate programs . teach More ›

As far aswoodworking projectsgo , few are as satisfying as those turn on a lathe . But what is a lathe ? A lathe is a power tool that spins chunks of Sir Henry Joseph Wood at high speed , allowing woodworkers to dress and mold them with sharp creature . Long shaped items like table legs , baseball game bat , and balusters are typically the products of study on a lathe .

But , woodturning(as the bit of using a lathe is call ) is somewhat of a nuanced art . It can be a little intimidate for those new to the woodworking humans , and knowing how to choose the best tools and how to use a lathe call for a bit of background signal orwoodworking class . Luckily , this guide will explain the basics .

Photo: istockphoto.com

Important Lathe Parts

Lathes come in several shape and sizes but generally control the same role , although on unlike scales . The following are some of the most significant lathe parts to jazz .

3 Types of Wood Lathes to Know

There are a few dissimilar types of Natalie Wood lathes to make love about , as each has its pros and yardbird in a impart situation . know the type of lathe on whirl will avail shoppers opt the vc for their indigence . But first , a bit of language :

Benchtop or Mini Lathes

Mini lathe are excellent for small woodturning projects like ornament and pens . They ’re able tosit on a benchtopwithout taking up much space , yet they have the power to spin small chunks of wood cursorily enough for turning .

Benchtop lathe always have DBCs of under 20 inches , and their sobbing are typically 8 inches or less . This gives them enough space to turn ornaments , pens , wine stoppers , and other small point or cunning while also stay on light and thick enough to move around the shop .

Our Recommendation : Shop Fox 1/3 - Horsepower Benchtop Lathe on Amazon for $ 289The Shop Fox W1704 feature a 1/3 - HP motor , a 12 - in DBC , and an 8 - inch SOB make it equal to of turning high - quality small cunning .

Photo: Amazon.com

Midi Lathes

Midi lathes have more power and capability than a mini lathe , and they are also a minute large . However , they can still accommodate on a workbench . While DBCs are n’t typically much longer , the SOBs are usually substantially duncish — generally by more than 12 in .

Midi lathes depart quite a bite from benchtop lathe in terms of business leader , price , and additional feature article . Adjustable speed , digital read-out , and more professional - grade features are uncommitted with midi lathes , despite these prick not take up much more space than their smaller counterparts .

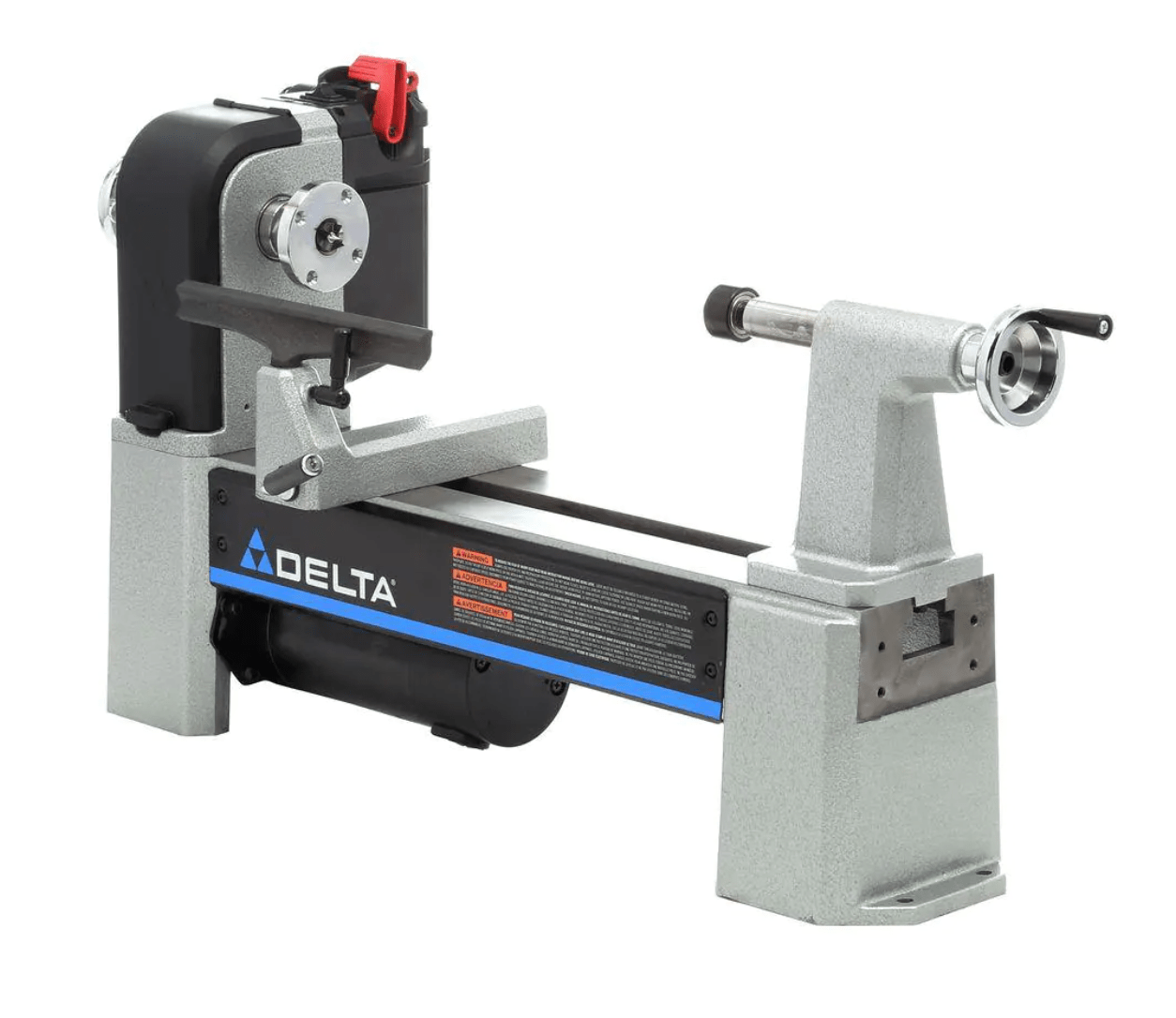

Our Recommendation : Delta 12 - 1/2 - Inch Variable - Speed Midi Lathe at The Home Depot for $ 1,041.02Delta ’s midi lathe feature a large 12 1/1 - inch golf stroke capacity , as well as a DBC of 16 1/2 inch , admit it to turn anything from a pen to a salad bowl , or even a short tabular array wooden leg .

Photo: Homedepot.com

Full-size Lathes

Full - size of it lathe are for larger turning undertaking like mesa legs and baseball game bat . These model typically have their own stands , and the working pinnacle is around 4 foot . Their DBCs often exceed 40 inch and their SOBs are unremarkably in the 15 - inch grasp .

These models are expensive , but for good reason . The wood stock they spin can be big , and these models require preciseness machining , tight tolerances , and powerful motor to do their occupation and keep the user safe . These lathe can also last a lifetime if ramp up by a reputable manufacturer .

Our Recommendation : Grizzly 16″ x 46″ Wood Lathe with Digital Readout at The Home Depot for $ 1,464Between the 43 - in DBC , a massive 16 - column inch SOB , and a repositionable headstock for faceplate turn , this full - size lathe has what it take to facilitate drug user make a variety of turned wood item in hobby garages and pro shop alike .

Photo: Homedepot.com

Lathe Safety Tips

New woodturners need to know that there are some inherentsafety risksinvolved with spin a chunk of forest at more than 1,500 RPM . As a natural cloth , wood ’s grain pattern and strength are not necessarily consistent throughout most pieces of store , and these patch have been known to fail and vanish off a lathe . For that reason , it ’s crucial to clamp a stock carefully at the dead center of the blood line whenever potential and always assume a face buckler while woodturning .

Another lathe safety wind is to primp cautiously . lathe whirl very fast and do n’t stop quickly , so getting a idle arm or long hair wrapped up can be disastrous . Be sure to avoid loose meet clothing and keep hair bind neatly back .

last , only usewood that seems to be in good condition , free from mile or fracture . Taking these safety equipment safeguard will serve keep the user safe while turning .

Photo: istockphoto.com

Essential Lathe Cutting Tools for Beginners

There are a few lathe cutting tools and differentiate instrument that all start out woodturners need to familiarize themselves with . Depending on the planned labor , they may be capable to bring them to their collection of cock one at a time .

There are more tool for a lathe than those include in the following inclination , but this list is a good offset for a beginner .

With thisbasic set of tools , tiro woodturners can create ornaments , pen dead body , small spindles , wood bowls , cups , and other small lathe projects in very minuscule time at all .

Photo: istockphoto.com

Initial Setup and Calibration

The first thing to do when correct up a lathe is to watch the case of centers involve . The stock promontory and tailstock work well for longsighted objective like spindles , while face sprain bowls may want switching to a circle of jaw . Each lathe changes revolve about somewhat differently , so refer to your particular model ’s manual .

After the Sir Henry Joseph Wood is clamped in the lathe , adjust the tool rest . It should be close enough to the wood to offer tool control condition and maintain a pivot man point far toward the death of the chisel while still let the wood to whirl freely without smacking the ease .

Also , it ’s effective to level your lathe car before starting . put the lathe on its work bench and place a point across the bed . Many lathes have adjustable ft that the substance abuser can turn to tweak their positioning , so adjust them as necessary to create a static , level al-Qa’ida .

Photo: istockphoto.com

How to Use a Lathe for Turning Wood

With the basic covered , learning how to apply a lathe for successfully turning wood is built on experience . However , the chase should avail get most drug user start .

STEP 1: Select the right blank.

The first step is choosing the correct blank piece of wood . Generally speaking , the best piece of woodwind instrument will be from a material that turn well . Hardwoods such asmaple , walnut , cherry , ash , and hickoryare all woodturner ducky , but deal like clear pine tree may even be enjoyable . Cut this while to its ruined duration before clamp it in the lathe .

Also , the forest should be free of knot or cracks . With time , woodturners will study how to correct and even incorporate imperfectness , but in the beginning , it ’s proficient to deflect them altogether .

STEP 2: Draw a plan.

Take a few minutes to draw a plan for the project . Draw the length , shape , curves , and other touches on a piece of newspaper publisher and pin it on the wall near the forest lathe . If potential , include thickness and length for each discussion section in monastic order to have a road single-valued function to follow .

Do n’t get too hung up on following this roadmap down to the millimeter at first . However , sustain a design to follow will aid you stay on track and build up newfound skill without wasting wood as readily .

STEP 3: Find the centers on each end.

It ’s important to clamp the clean as close to the center as possible on each end . Do this by using apenciland a steel ruler .

stretch out the brand rule from across two opposing corners and line a pipeline along the edge of the formula . Flip the brand ruler to the other two fight down box and repetition . The two lines should cross at the dead center of the clean . reiterate this procedure on the other end of the blank , as well .

STEP 4: Clamp the blank in the lathe.

set one end of the board against the headstock ’s center point , adjust the tip with the shopping mall mark . Maintaining pressure against the wood and headstock , slither the tailstock toward the blank , align the other shopping mall mark with the tailstock ’s full point .

Check to ensure that each end is aligned in good order . Once satisfied that everything is where it ’s theorise to be , lock in the tailstock in place with the lever . stiffen the tailstock using the hand crank . Tighten firmly .

STEP 5: Adjust the tool rest.

Be sure to adjust the tool rest before starting the lathe . It should be close enough to the workpiece to provide mastery , but far enough aside that the gillyflower does not scratch it when swing by hand . A honest world-wide length is 3/4 of an in , but experient turners will learn what works for them over time .

Unlock the eternal sleep ’s base from the bed and slide to where it postulate to be . Adjust it in or out to the desired distance before locking it back down against the bed . Next , adapt the height so it ’s somewhere around the middle of the line of descent , but the exact height should allow the drug user to hold their carving peter well .

After positioning the tool rest , spin the stock to ensure it wo n’t strike the rest .

STEP 6: Turn on the lathe.

Put on your face buckler and power up the lathe . permit the lathe to get up to pep pill and brace before proceed on to carve . It ’s a good idea to stand to the side of the lathe closest to the index clit upon inauguration .

Watch for any severewobble or vibration in the latheand at once shut down the lathe if a wobble is notice . The lacuna may not be centered or its natural chassis may make it unusable for a lathe .

STEP 7: Start roughing.

Place the roughing chisel on top of the shaft residue . Applying unclouded pressure with a firm adhesive friction , slide the chisel forward until it begins to get in touch with the workpiece . body of work slowly , taking off humble routine of the corners at a time until the blank is smooth and cylindric . Move up and down the cock repose . If it ’s necessary to reposition the remainder , sour the lathe off and let it come to a over quietus .

Getting too belligerent can cause tear - out in the workpiece and send chunk of Sir Henry Joseph Wood fly . Also , the roughing chisel may tone down faster if force into a spinning workpiece .

With the workpiece cylindric , it ’s time to follow the plan draw in dance step two . Use the parting chisel to score sections of the spindle excogitation . Next , use spindle gouge to cut the shapes of the arbor . body of work slow to make politic curve and transitions , and when necessary , move to differently - sized chisels .

verify to keep up contact with the cock rest the entire time . Also , apply the calliper to check the diameter of the workpiece often .

STEP 9: Sand the workpiece.

Turn the lathe off and let the workpiece hail to a plosive speech sound . Swing the prick rest out of the way and lock it back down or remove it altogether . set out the lathe again and let it get back to speed .

With the workpiece spinning , cautiously defy a piece ofsandpaperagainst the workpiece , sliding it up and down until the surface is smooth . If desired , move to a finer grit and retell for an highly fluid finish .

Lathe Maintenance Tips

Keep your lathe destitute from wood bit , dust , and debris . Usecompressed airand an air choke to spray belittled bit of Sir Henry Wood from around the headstock , tailstock , and motor . practice a lint - free material to wipe down the headstock , tailstock , and any machine threads or holes .

Additionally , lubricate the lathe ’s seam , tailstock , and mitt crank with a bit of pervade oil . Be certain to earmark it to dry out before turning on the lathe or it could catapult grease around your shop .

While this is more of a need for the workspace than the lathe itself , be sure to brush away Ellen Price Wood chips and shavings . Not only are these possible slip or trip hazard , but lots of potato chip are fire peril . Be sure to make clean them up after each turning session .

Final Thoughts

Whether it ’s arbor , table ramification , pens , stadium , ornaments , or other item , all it consider is a small basic knowledge and careful practice to get started work with a lathe . While the prick may seem intimidate , and there are some safety considerations to keep in mind , woodturning can be a fantastic sideline . DIYers can make natural endowment or slyness , and mastering the graphics can be a lifetime interest . That pursuit has to start up somewhere , and reading this guide on how to use a lathe could be just the kickstart involve to head down this rewarding course .

The prices listed here are accurate as of issue on August 31 , 2022 .

This Is the Year for a Kitchen Renovation

Whether you ’re selling or staying , everyone can get something out of a kitchen update . Learn why we consider this redevelopment the Most Valuable Project of 2025 and how to remain on budget .