We may earn taxation from the mathematical product available on this page and participate in affiliate programs . memorize More ›

Whether it ’s for thin out framing lumber square and true , or cut a perfect crown molding joint , a miter saw can be indispensable . Miter saw use range from rough framing to dress and complex woodwork , and this mogul prick allow users to cut through dense materials quickly , accurately , and safely , flattening much of the learning curve of DIY - ing .

However , if you do n’t hump how to use a mitre joint saw , they can be extremely daunting . With a bit of cognition and praxis , this is one tool that ’s well-fixed to master . Keep reading to find out more .

Photo: Tom Fenenga for Bob VIla

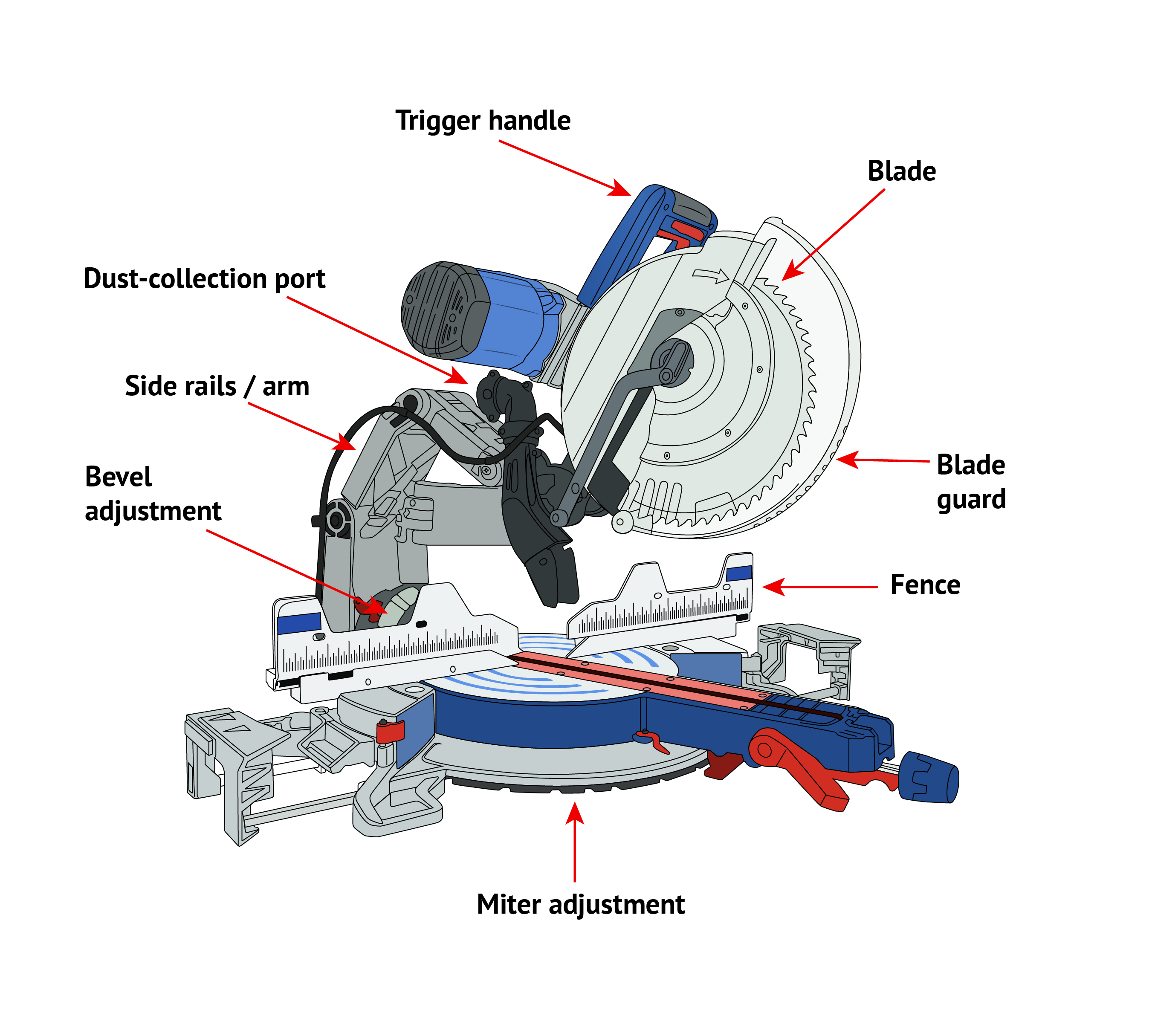

Parts of a Miter Saw

3 Types of Miter Saws

What is amiter saw ? It ’s a power instrument with a pivoting arm and spinning blade that quickly and accurately cut materials like woodwind , plyboard , MDF , and plastic . In some case , metals can be edit out by a miter adage , too .

A ability mitre saw can be one of three main type , and each has its pros and sting . One type might be better for a particular projection or budget than another ; it ’s a thing of recognise a bit about each type and choosing the safe for the office .

1. Miter Saw

A standard miter saw has an adjustable base that the user can align to cut angle in either direction . As the name implies , it ’s equal to of write out miter and straightforward buttocks joints . The leaf blade does n’t cant over , though , so all snub will have 90 - level ends . These saws are typically most useful for simple framing and woodworking projects .

Our Recommendation : DEWALT 12 - Inch Miter Saw 15 - Amp Single Bevel on Amazon for $ 229

For around - the - household trimming and crosscutting , the DeWalt 12 - column inch single chemical compound miter saw has all the necessary power and precision without a large price tag . It make out boards up to 8 inches across-the-board and cut bevels in one steering . It total with a microscope slide - out fencing that offer to help support the board being rationalise . For rubber , the DeWalt see also have a mechanism that mechanically locks the spring arm in the “ down ” military position unless it ’s manually unbarred with a button on the back .

Illustration: John B. / Fiverr

While technically a individual - cant compound mitre joint saw , this model is about as basic as it gets these twenty-four hours . There are n’t any extra bell and whistles , as DeWalt chose to centre on quality and affordability over features .

2. Compound Miter Saw

Compound miter adage have adjustable groundwork and adjustable arms , allowing the user to change the angle and the tilt or bevel of the blade . Beveling allow for more flexibleness and capability than a standard miter sawing machine , making these adage ideal for trim workplace and frame up alike . And , despite the surplus feature , learning how to use a chemical compound mitre find out does n’t have to be overwhelming .

Our testimonial : Metabo HPT 12 - Inch Compound Miter fancy at Lowe ’s for $ 329

The affordable Metabo HPT 12 - Inch Compound Miter go through with laser guide cuts bevel in both directions and come with a brawny 15 - ampere motor , to flush . Thanks to the Xact Cut moderate Shadow Line System , the cutline is loose to see on the board before cutting , which can help reduce errors .

Photo: Amazon

3. Sliding Compound Miter Saw

slide chemical compound mitre joint saws are just like compound miter saws except that the power saw rides on a rail or sleeve . This conception reserve users to pull the saw head toward themselves and then push it through the workpiece . This give these saws much wide of the mark cut capacities , but they ’re typically sonorous and more expensive . Keep in thinker that learning how to use a skid miter power saw is n’t much more difficult than using a received adage , so the capacity might be deserving the extra investment .

Our passport : BOSCH Power Tools GCM12SD Sliding Glide Miter Saw on Amazon for $ 599

The Bosch Power Tools GCM12SD Sliding Glide Miter Saw is a 12 - inch mitre attend with a slither arm that allow the user to cut plug-in up to 14 inch extensive . The saw comes with pull - out material financial support on both side to stabilise boards up to 40 inch long , and it cuts compound bevel in both directions .

Photo: Lowe’s

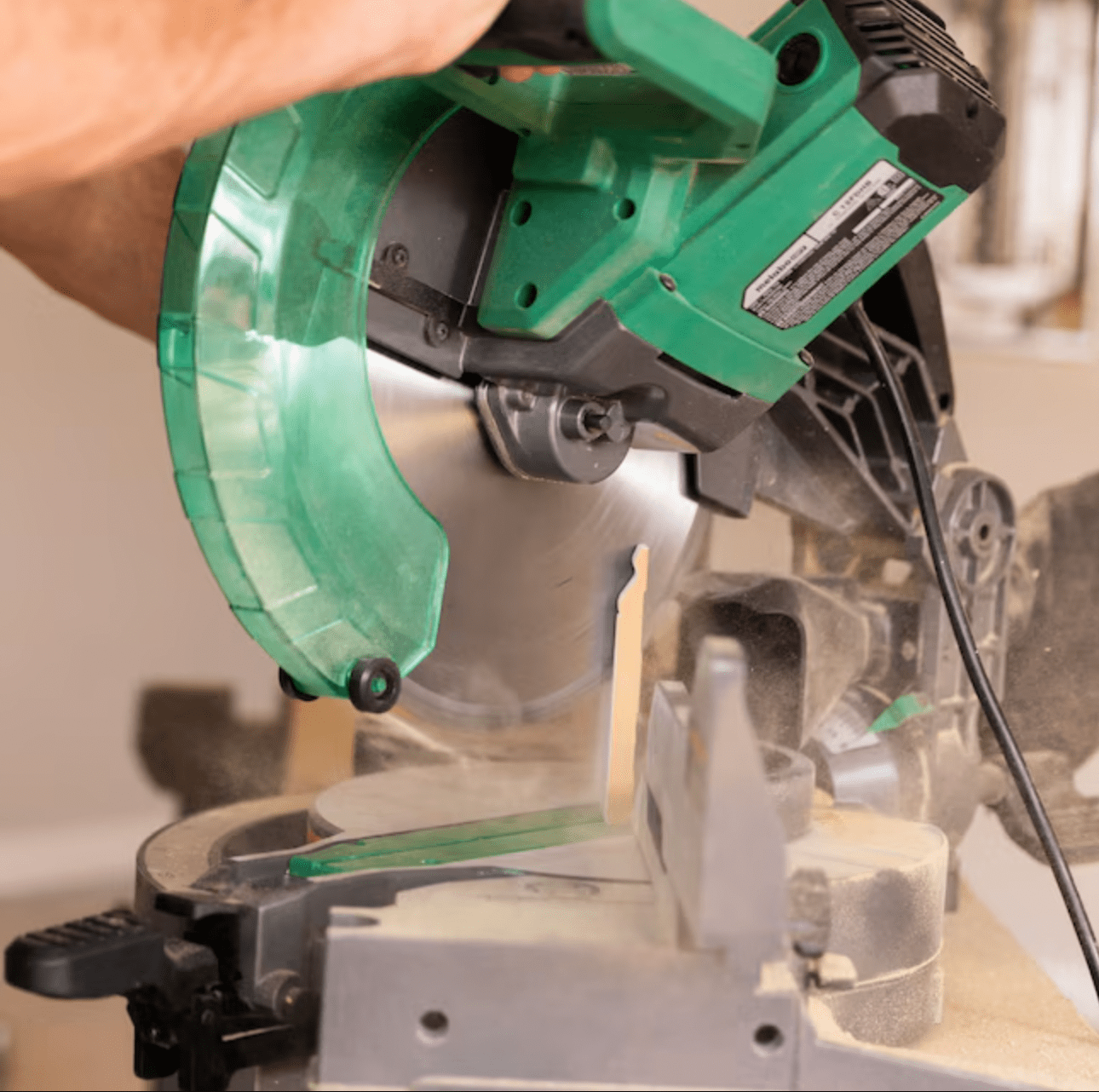

The clear saw sentry duty on the Bosch mitre joint saw is design not to embarrass the user ’s sight of the undercut throughout the entire mental process . The trigger handle features an ergonomic grip that can be used by either flop - handed or left - handed users just as comfortably , and it features a padded nonslip grasp . Fences are adjustable , and the miter weighing machine numbers are etch into the untarnished steel .

Miter Saw Safety Tips

Initial Setup and Calibration

First , learn how to adjust up a miter go steady by referring to the manufacturer ’s book of instructions . Install any clamps , hold pile , lasers , adjustment handles , and junk collection bags before secure in the saw . Become intimate with the bevel adjustment , angle releases , gun trigger , base hit , and blade guard first .

Next , calibrate the saw , as even new miter saw might involve standardisation . Start by checking the blade with a compounding foursquare . The blade should be perfectly perpendicular to the fence and perpendicular to the radix . Test it by cutting a piece of combat lumber down the middle at 90 degrees . impudent one of the halves over and line it up with the other one-half . These two piece should be absolutely straight and flat . If not , conform the sawing machine .

Once the blade is aligned , check to ensure that the laser ( if so weaponed ) aligns with the vane by performing a cut and see where the laser lands . If it ’s out of conjunction , correct it according to the manual .

Photo: Amazon

How to Use a Miter Saw for Miter Cuts

Miter cutscan be difficult to carry through by hand , but miter joint saw make them a piece of cake . Luckily , acquire how to cut angles with a miter saw is a straightforward process .

Step 1: Set the miter angle.

To find the right slant , expend an slant gauge and part the version in one-half . So , for 90 degree , prepare the saw at 45 degrees . After cutting two boards to 45 degree and tack them , they ’ll form a 90 - degree slant .

undo the adjustment knob , and swing the saw blade to the correct slant . Once at that angle , deform the thickening to stiffen the blade in place .

Step 2: Place the workpiece on the saw.

If the byword is in the “ down ” position , lift it by unlock the pin in the back . lay the workpiece on the saw . Without activating the sawing machine , lower the blade and adjust the workpiece so the interior of the blade is aligned with the cut fall guy . If it seems that the cut side may fall , deploy the delay - down clamp and tighten it onto the workpiece .

Step 3: Start the saw and cut the workpiece.

With the support hand safely away from the brand , embrace the safety initiation and then the trigger to commence the power saw . let the saw blade to spin for a few moment to build speed . lento lower the saw into the workpiece until it cut all the way through . publish the gun trigger , and set aside the blade to check before snarf the saw .

Step 4: Repeat for the other half of the miter.

Unlock the adjustment knob , and drop the saw to the opposing slant . Lay the saw workpiece on the sawing machine , align it with the blade , clamp the workpiece down , and contract the workpiece in the same fashion as before . scene the two cut objet d’art together to see to it the slant is correct .

How to Use a Miter Saw for Bevel Cuts

There are many cause you might need to make a bevel issue with a mitre saw . Whether it ’s for a compound mitre consisting of two dissimilar angles , or for back cutting a part of trim for a tighter fit , here ’s how to make a bevel cut with a miter joint saw .

Step 1: Adjust the saw blade’s angle.

Locate the cant adjustment knob in the back of the saw and relax it . Many chemical compound miter saw also have a peg that locks them from beveling in both direction , so if the sawing machine is n’t tilting in the desired direction , pull this peg out as well .

Adjust the blade to the desired angle by watch the indicator and gauge turn up near the knob . Once the blade is at the correct angle , tighten the knob so it can not move .

Step 2: Ensure the fence is clear.

Depending on the sawing machine , there might be a section of fence that the substance abuser must remove before bevel cutting . in general talk , these obliterable section tighten in position with a set of backstage nut and are easy to withdraw without tool . Some even just swivel out of the way . Without become the power saw on , lour the leaf blade to assure it ’s absolved of the fencing .

Step 3: Align the workpiece with the blade.

localize the workpiece on the byword and lower the blade . insure that the interior of the very low-toned tooth lines up with the edge of the cutline . conform as necessary without scraping the blade against the workpiece . Once congeal , tighten the time lag - down clamp to keep the workpiece from move or jumping when the saw kick on .

Step 4: Cut the workpiece.

With the support hand safely aside from the blade , squeeze the refuge gun trigger and the trigger to start the proverb . Allow the examine blade to spin for a few moments to work up speed . tardily lower the saw into the workpiece until it make out all the way through . free the gun trigger , and allow the blade to stop before pinch the power saw .

Pro crown : The sawing machine will travel at the set angle , so do n’t seek to pull it directly down . This will cause the leaf blade to deflect and result in a poor cut .

Miter Saw Maintenance Tips

There are a few thing that require to be done on a regular basis to maintain a mitre adage .

Final Thoughts

mitre joint adage might sense restrain , but DIYers should n’t be frightened of them . The minute that a DIYer summate a high - quality miter get wind to their collection , they ’ll be able-bodied to take on a whole new category of projects . By putting the tips above into pattern , watch how to operate on a mitre image safely and accurately will become second nature .

Prices quote in this clause are accurate as of December 11 , 2024 .

This Is the class for a Kitchen Renovation

Photo: Tom Fenenga for Bob Vila

Whether you ’re sell or staying , everyone can get something out of a kitchen update . determine why we consider this renovation the Most Valuable Project of 2025 and how to stay on budget .

Photo: Tom Fenenga for Bob Vila

Photo: Tom Fenenga for Bob Vila

Photo: Tom Fenenga for Bob Vila

Photo: Tom Fenenga for Bob Vila

Photo: Tom Fenenga for Bob Vila

Photo: Tom Fenenga for Bob Vila

Photo: Tom Fenenga for Bob Vila