We may realise receipts from the product uncommitted on this page and participate in affiliate programs . Learn More ›

Especially important when it comes tocar maintenance , a torque wrench tightens bolts to a specific torque level , ensuring that the fastener is slopped enough before completing a job . If a part of the fomite — like the lugsail nuts — are not properly tightened , they may loosen or come apart whole during operation , posing a grave hazard .

To ensure that a torque wrench is exact , it ’s necessary to contain the calibration of the twist before utilisation . Typically , user can calibrate torque wrench accuracy to within ±4 percent , though top - of - the - line intersection may have a more exact accuracy range .

Photo: istockphoto.com

Find out how to use a torsion pull , how to fit the truth standardisation , and more with this informative guide .

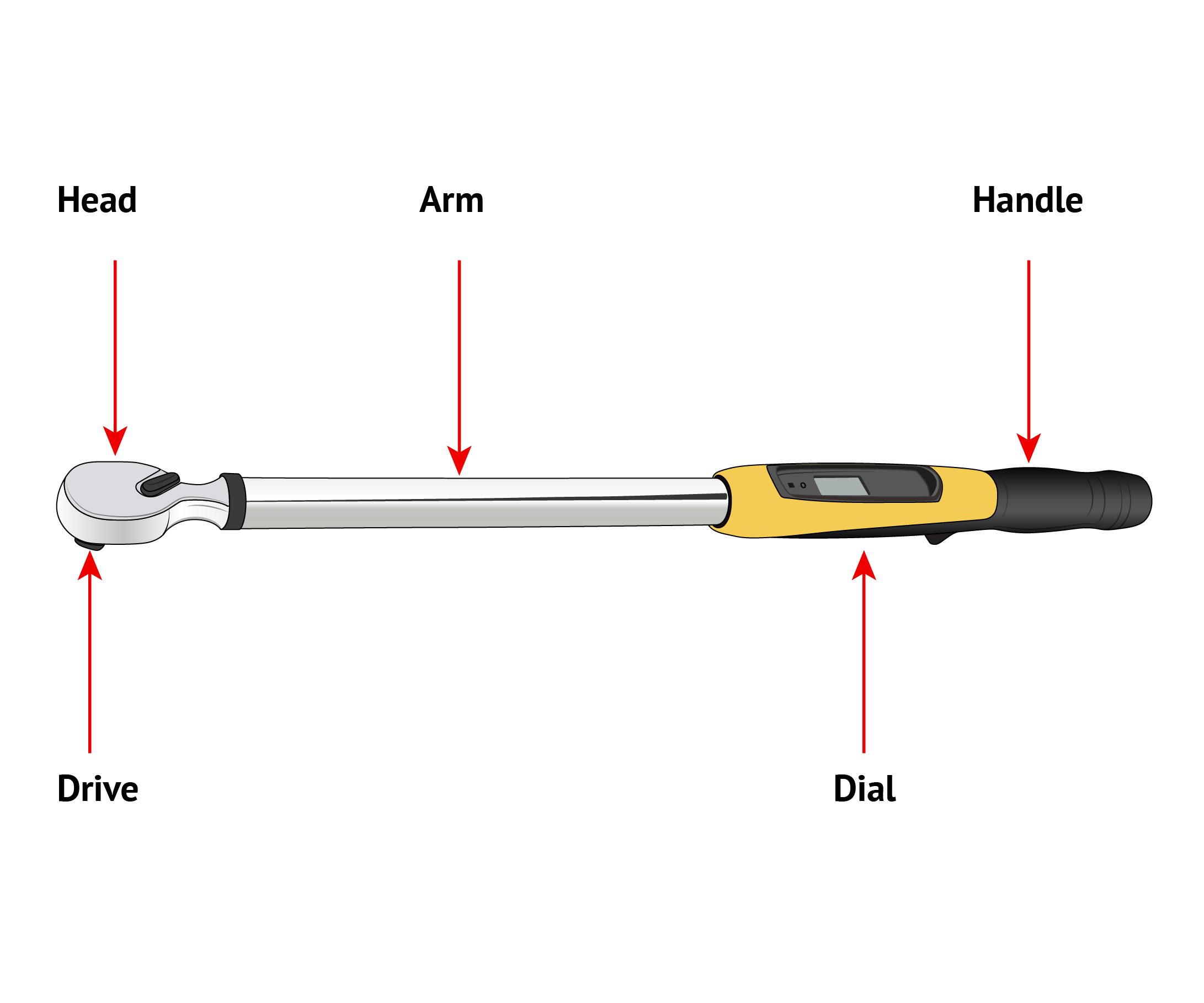

Parts of a Torque Wrench

Before get wind how a torsion wrench works , it ’s a serious idea to get familiarize with its parts . Once you know its key component you ’ll be in a position to see how to mark a torque wrench and how to line up a torsion wrench so that it can be calibrate for future habit .

3 Types of Torque Wrenches DIYers Should Know

There are a variety oftorque twist typesthat can be used to make for on cars , trucks , bicycles , motorcycle , and any other vehicle or piece of equipment that involve accurate bolt and nut tightening . The most usual torque wrench types include beam , click , and digital torque wrenches .

1. Beam

radio beam - style torque wrenches do n’t rely on anything except the flex of the pull to measure the torsion on the fastener . drug user can correspond the current torque being exerted on the fixing with a scale dial , locate near the handgrip .

When force is apply to the spanner , the irradiation or arm of the wrench twist slightly , change where it intersects the scale of measurement to provide a meter reading of the current amount of torsion on the fastener . This eccentric of torsion pull is relatively inexpensive and does n’t require frequent calibration or maintenance .

Our Recommendation : Get the Tooluxe ⅜- and ½-Inch Dual Drive Beam Torque Wrench at Amazon for $ 19.97.Made of harden alloy steel , this simple , efficient beam - expressive style torque spanner comes with both ⅜-inch and ½-inch cause for improved versatility .

Illustration: John B. / Fiverr

2. Click

A click torque wrench is the most ordinarily used type of torque twist due to the blue cost , relatively simple maintenance , and because it can be set to a specific torsion stage , so users know when to arrest apply force to the twist .

If the user applies enough torque to reach the situated level , the click - style torsion wrench makes an hearable click sound . When the pull clicks , this is an indicant that it ’s clock time to halt tightening the fitting . If you overtighten the nut or bolt , the fastener may flex , crack up , or separate entirely .

Our Recommendation : Get the Tekton ½-Inch Drive Torque Wrench at Amazon for $ 38.79.The click - style torque twist by Tekton has a ±4 percent accuracy evaluation and full steel construction , improving the overall durability of the tool .

Photo: Amazon

3. Digital

Digital torque wrenches are a step up from click - style wrenches with clear torsion readings on a digital cover . Somedigital torque wrenchesmay permit the user to put multiple torque levels , make it well-heeled to quickly shift between everyday automotive tasks with the pushing of a button .

Similar to click - stylus torque wrench , a digital torsion twist will typically notify the substance abuser with a bombination , bleep , vibe , flashing Inner Light , or some combining of these warning machine to help forbid overtightening . Just keep in mind that this type of torsion twist requires batteries , so it ’s a adept idea to have new barrage fire on hand to obviate interruptions .

Our passport : Get the Gearwrench ½-Inch Drive Electronic Torque Wrench at Amazon for $ 149.97.Ensure the most accurate torque meter reading with this electronic torque pull that sport a minute ±2 percentage truth evaluation .

Photo: Amazon

Torque Wrench Safety Tips

Before using a torsion wrench , it ’s recommended to audit the creature and any socket or fastener that will be used with it . If the twist or any accouterment are crack , dent , or warp , these parts should be replaced before proceeding . Similarly , if a torsion twist is dropped on the ground or pink against a backbreaking object , user will require to put the labor on clench until they can recalibrate the wrench . This is because the impact from drop or strike the wrench can throw the cock out of calibration .

Additionally , it is important to ward off using the torque wrench to loosen nut case , bolt , or any other character of fastener . These sore tools are only designed for tightening . Using the torque wrench to untie a fitting can reduce the truth of the tool , call for more frequent calibration to keep the torque wrench functioning decently .

Initial Setup and Calibration

calibrate a torque twist is n’t overly hard , though it ’s important to proceed lento through these steps to check the truth of the tool . Users will need a judiciary vise , a 20 - pound weightiness , a thin rope or string ( capable of holding at least 20 pounds ) , and a measuring taping .

How to Use a Torque Wrench for Tightening Lug Nuts

Step 1: Select the correct drive size and sockets.

Torque twist drives can browse from a ¼-inch size for small machinery , like motorcycles , mopeds , or lawnmowers , to 1 - column inch campaign for shape on monolithic vehicle , like a semi - truck . The appropriate size for tightening lug nuts is a ½-inch drive . ensure you have the right size socket to suit the drive before proceedings .

Step 2: Set the torque level.

The next measure is to set the trust torque level . If you are using a beam - mode torque wrench , then you may skip this step , but if you have a click - style or digital torsion wrench you may take the target torsion economic value on the wrench .

practice the digital mastery to increase or fall the torque economic value on a digital torque wrench . With a click - vogue torsion pull , you may fix the torque level by twisting the handgrip so that it line up with the desire torsion level on the telephone dial .

Step 3: Position the torque wrench and tighten the fastener.

handwriting constrain the lug nuts as much as possible , then slew the torque wrench socket onto the first Lugh junkie . Turn the torsion wrench to tighten the lobworm nut . If you are using a beam - manner torsion pull , keep an heart on the telephone dial and stop utilize effect to the pull when you have reach the target torque degree .

If you are using a click - style or digital torsion spanner , apply force to the fastening until you pick up a click , beep , or any other auditive or optic signaling that indicate you have reach the specified torsion tier . Keep in mind that while some digital torque twist have programmable margin limits to prevent overtightening , this is n’t a stock feature . check that to discontinue apply force when the alarm indicates the fixing is at the destine torsion level . Repeat this operation with the remaining lug nuts to finish tighten the wheel .

Torque Wrench Maintenance Tips

torsion wrench are specialized tools that can be thrown out of standardization if they are dropped or knock against a tough airfoil . If the tool is dropped on the primer coat , then it will need to be recalibrated before it can be used . When properly cared for , a torque twist can keep on its accuracy , so you do n’t require to calibrate it before every consumption . Just make certain to store the torque wrench in an appropriate example when it ’s not in use . Keep the twist adequately calibrate when it ’s not used by exchange the torque set to the manufacturer recommended level before salt away the tool .

Final Thoughts

As mentioned above , torsion wrenches should never be used for loosening fastener , as this can get long-lasting damage to the peter . Only practice a torque twist for the design of tightening a fastener to a specific torque level , such as when you arereplacing Muriel Sarah Spark plugsorchanging a tyre .

When not in economic consumption , this sensitive tool should also be proceed safe in a case or reposition container to help ensure the machine remains adequately calibrated . For those who are give difficulty deciding on the good type of torque wrench to add to their shop , a click - expressive style torque wrench is both low-cost and relatively easy to use . If price is n’t a deciding ingredient , a digital torque wrench provides better accuracy and may be easier to use . enquiry potential options and select the right type of torque wrench to expeditiously plow the job .

The prices name here are accurate as of issue on December 17 , 2024 .

Photo: Amazon

This Is the Year for a Kitchen Renovation

Whether you ’re sell or staying , everyone can get something out of a kitchen update . Learn why we consider this renovation the Most Valuable Project of 2025 and how to rest on budget .

Photo: iStock

Photo: iStock

Photo: iStock