Best Overall

Minwax 42853000 Stainable Wood Filler

Best Budget

J-B Weld 8257 Kirkwood Wood Repair Epoxy Putty Stick

Best Epoxy

Abatron WoodEpox Epoxy Wood Replacement Compound

We may make receipts from the products available on this Sir Frederick Handley Page and participate in affiliate political platform . Learn More ›

Mrs. Henry Wood fillers aid enshroud the appearance of cuts , cracking , and nail hole inpainted or terminate woodtrim and article of furniture , but they are also often used to fill in gaps that remain after put up dry wall or installing a new door frame . The best way to ensure that guest never notice the bandage is to invest in a stainable mathematical product that has a texture similar to that of the contiguous wood . We put five of the top stainable wood fillers to the test to watch which ones do the best .

Finding awood fillerthat flux well with the Sir Henry Joseph Wood type , is easy to give , and does n’t cost a portion is key to getting full results . After testing each wood filler on a variety of wood surfaces , we foundMinwax , with its well-heeled - to - function design , ranking finish , and affordable price to be the best of the bunch . Read on to discover more of the good stainable forest fillers on the market and to learn more about our test answer .

Our Top Picks

The product below are our top pick for some of the best stainable wood filler establish on tone , damage , and the shopping considerations mentioned above . Regardless of the specific attributes of a wood undertaking , there ’s a stainable makeweight below that gibe the bill .

Our Ratings : Ease of Use5/5 ; Appearance4.5/5 ; Durability4/5 ; Value5/5

Minwax wood filler yields excellent results , is easy to apply , and does n’t cost much , which is why it tops our lean of wood filler . With its latex - based expression , Minwax has a smooth clay - like eubstance that is very easy to spread over declamatory and smaller gaps and cracks . There were no gawk to work around , and it was flimsy enough that we did n’t need to apply our fingers to use it . We were able to fill a ¾-inch diam hollow that was ¼-inch deep with relief .

Whereas other wood filler took hour to dry out , Minwax is a fast - dry liquid Mrs. Henry Wood filler , ready for sanding in smaller pass in under an hr and for larger jobs in about four hours , speeding along the job so we could move onto the staining phase . It also does n’t shrink as it dries , so there was no need to practice a 2nd layer to fill in gap . Once ironical , the makeweight ’s smooth consistence meant that it was well-fixed to sand the control surface down to a stainable finish . Though not quite as stiff as some of the cellulose - base wood filler we ’ve tried , Minwax still hold up well to bump and knock once dry and to the full cured . Minwax also pack the stain well , and its instinctive woods color was a cheeseparing match to our pine tree dining table .

What our examiner says:“Minwax has that just right consistency for filling in tiny nail kettle of fish or larger crack . I was able-bodied to make even with child repairs with a single applications programme , which is n’t the norm with most wood filler . ” — Tony Carrick , Product Reviews tester and writer

Get the Minwax wood filler onAmazonor atLowe ’s .

J-B Weld 8257 KwikWood Wood Repair Epoxy Putty Stick

Our military rating : easiness of Use5/5 ; Appearance4/5 ; Durability4/5 ; Value5/5

sugar , dent , and nick occur frequently around the family , and they ’re commonly not orotund enough to warrant a full pail of wood makeweight . However , once enough of those small imperfectness have accumulated , you ’ll want to fixate them . This J - B Weld epoxy - based stainable wood makeweight is affordable and can be applied quickly with just your fingers .

The 3.5 - inch - long tube of makeweight has two disjoined part of an epoxy resin formula that you massage together to prep . If you do n’t mind incur your fingers a little dirty , JB Weld is very loose to use . We could pinch off a very precise amount of the makeweight , press it together to flux , and its Play - do - like consistency made it easy to push into low gap and cracks with our fingers .

Photo: Tony Carrick for Bob Vila

Kwikwood does have noticeably larger particles of Mrs. Henry Wood in it than other filler . While this helped to create a unassailable , hard haunt , it also made it more ambitious to achieve a smooth finish that was floor with the surrounding wood . We spent more prison term during the sanding phase to blend it equally with the surrounding wood surface than we did with some of the other wood fillers we screen .

genuine to its name , Kwikwood dry out quickly , taking between 20 minutes to set for a shallow repair and about an hour for our larger ¾-inch in diameter , ¼-inch deep divot . While this made for a quick turnaround time , we found that Kwikwood did n’t obligate Grant Wood stain peculiarly well . The instructions advise mixing the stain into the filler before utilise . This cognitive operation was mussy and the filth did n’t mix equally into the filler . These characteristics make it a beneficial choice for fast repairs on surface you intend to paint over or deal but not idealistic for filling microprocessor chip , cracks , or nail holes on stained article of furniture .

Get the J - B complex Weld wood makeweight onAmazonor atLowe ’s .

Photo: Tony Carrick for Bob Vila

Our rating : Ease of Use4.3/5 ; Appearance4/5 ; Durability5/5 ; Value4/5

While most wood filler are rated for indoor and outdoor use , they lack the durability of Abatron WoodEpox epoxy resin - establish wood makeweight , which has a formula specifically designed to resist mold , mold , rot , and water . Once the stainable and paintable woodwind makeweight is teetotal , it will remain permanently bonded to the Mrs. Henry Wood around it and will not shrink over sentence or with convert weather weather . This ability to ward off Mother Nature make the rainproof , solvent - free Mrs. Henry Wood filler a good resolution for repairing deck , out-of-door wood furniture , and other out-of-door carpentry .

WoodEpox comes in two separate containers that are mingle in equal parts to produce 12 ounces of filler . Divvying out adequate parts and immix them in a disjoined container made the software process a little more complicated than most wood filler . like to other epoxy resin woodwind instrument fillers , we found that the best mode to mix the two - part compound was by rub down it with our finger . Once sundry , the putty - like consistency allowed us to crowd WoodEpox into cranny and divot with proportional ease .

Photo: Tony Carrick for Bob Vila

WoodEpox dried in about an 60 minutes for our shallow fix and in a few hours for our larger divot mending . Since WoodEpox has a smooth consistency , it was comparatively easy to sandpaper . And while it throw soil well , it dries to a lighter white body that does n’t match lifelike wood colour , thus throttle its use of goods and services topainted surfacesand dark opaque stains .

Get the Abatron Grant Wood makeweight atAmazonorWalmart .

Best for Furniture

Goodfilla Water-Based Wood & Grain Filler

Our Ratings : Ease of Use4.7/5 ; Appearance5/5 ; Durability5/5 ; Value4.5/5

With its great colouring - cope with quality and smooth consistence , Goodfilla is a favorite for pass water resort to forest article of furniture . The cellulose - base , stainable wood filler has a finishing that resembles the food grain and vividness of rude cherry oak . If the initial people of color does n’t quite equalise the be flooring or article of furniture , the makeweight can be mixed with stains , tints , pigments , or dyes to reach the perfect shadiness .

You get what you make up for with Goodfilla . While it was sure enough the priciest of the wood makeweight we test , it also perform well than any of them . Its consistence is smooth and butterlike , which made filling everything from small nail pickle to large ¾-inch divots easy . Goodfilla dry out quickly , is easy to sand , and has no shoplifting , so there was no need for a 2nd coat on any of our trial run pieces . It dries to a careen - tough shell that held up to our effort to chip and indent it . Goodfilla also did the best job of matching the smother wood gloss , and we found it to be one of the good Ellen Price Wood filler when it number to receive stain .

Photo: Tony Carrick for Bob Vila

While Goodfella ’s high price tag may not make it a good option for basic job , such as occupy nail holes in skirting board , it ’s certainly deserving the cost if you ’re repairing microprocessor chip and cracks in wood furniture and other finish woodworking .

What our tester says:“I do it how easy this Cartesian product is to implement . It goes on smooth , fills even larger holes well , and sand down to an even polish that matches scanty woods seamlessly . ” — Tony Carrick , Cartesian product Reviews tester and author

Get the Goodfilla grain filler onAmazonandWalmart .

Photo: Tony Carrick for Bob Vila

Best Cellulose Based

Elmer’s E887Q Stainable Wood Filler, 3.25-Ounce

Our rating : relaxation of Use4/5 ; Appearance5/5 ; Durability4/5 ; Value4/5

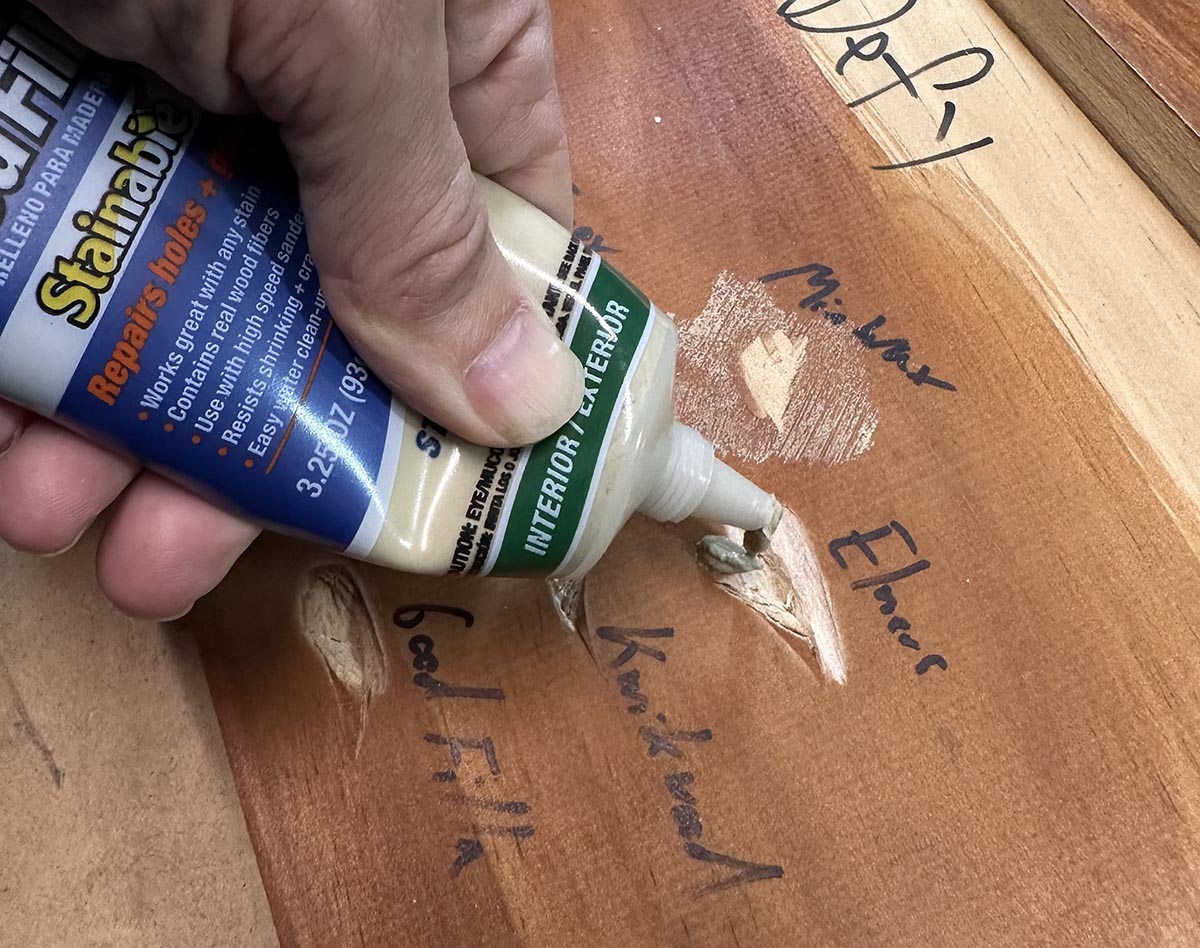

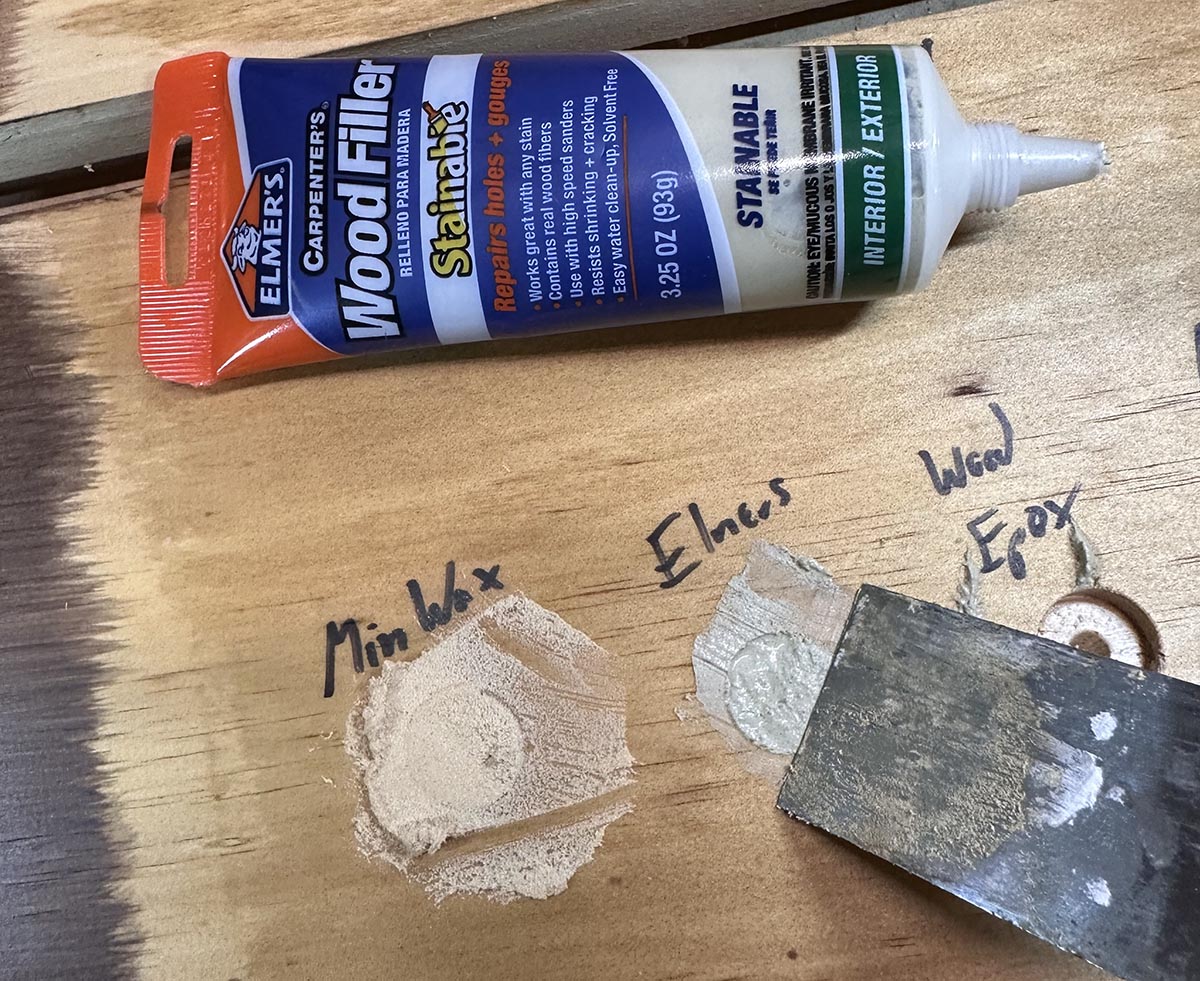

Cellulose - base , stainable woodwind makeweight like this one from Elmer ’s use fiber that copy the feel and coming into court of real Ellen Price Wood . In its squeeze bottle cast , Elmer ’s is designed to be an easy and cheap location for small reparation , including cracks , silicon chip and nail hole .

Elmer ’s was the only Grant Wood filler we essay that uses a squeezing nursing bottle plan , and we had motley feelings about it . The small applier point , pair with the compact body that ’s characteristic of a cellulose - base forest filler , made it a challenge to squeeze makeweight out . We found that knead the nursing bottle with our fingers prior to removing the detonating equipment and cut a gravid opening on the tip helped to make squeeze makeweight out of the feeding bottle an easier process . But while we were able to coax enough wood filler out to handle small repairs , this is distinctly not a Ellen Price Wood makeweight designed to handle larger ones , such as our 3/4 - column inch diam divot .

Photo: Tony Carrick for Bob Vila

That say , the convenient squeeze nursing bottle plan made it a nimble and gentle option for filling nail muddle and small chips . We were able to squeeze out a dab onto the repair and scrape off excess with a putty tongue . Elmers also dried to a severe consistence rapidly and was relatively well-heeled to sand . Once dry , it was a close match to innate wood color and held stain and paint well .

Get the Elmer ’s stainable wood filler atAmazon .

Jump to Our Top Picks

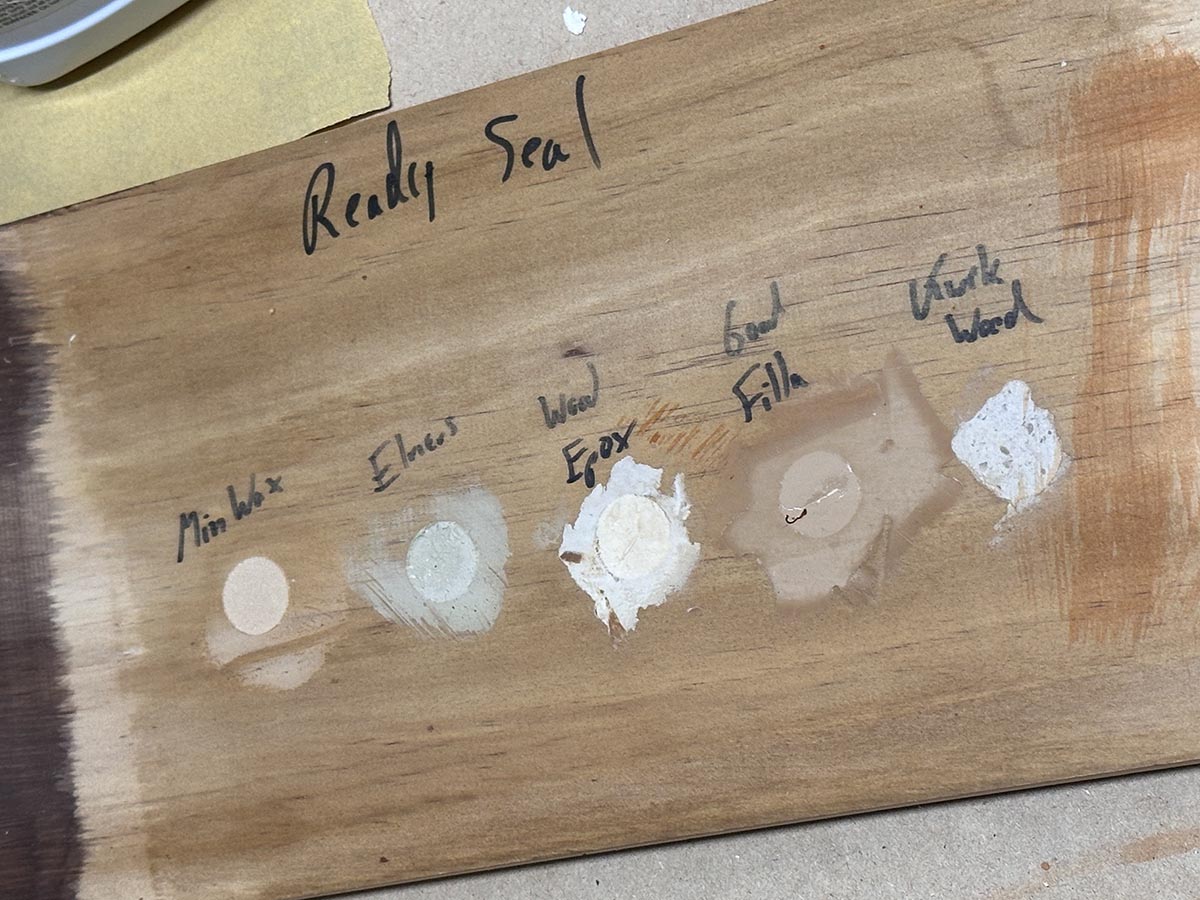

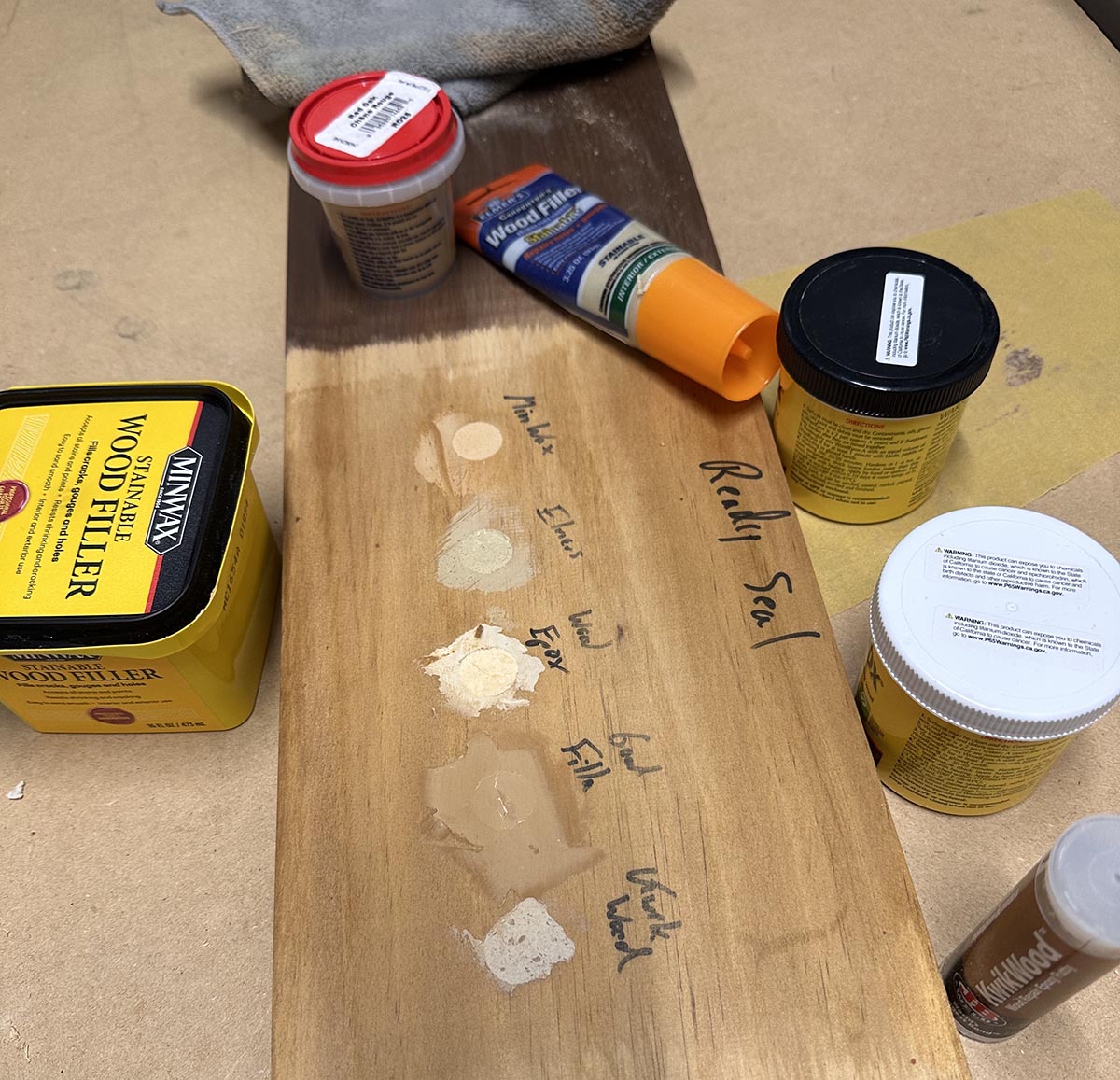

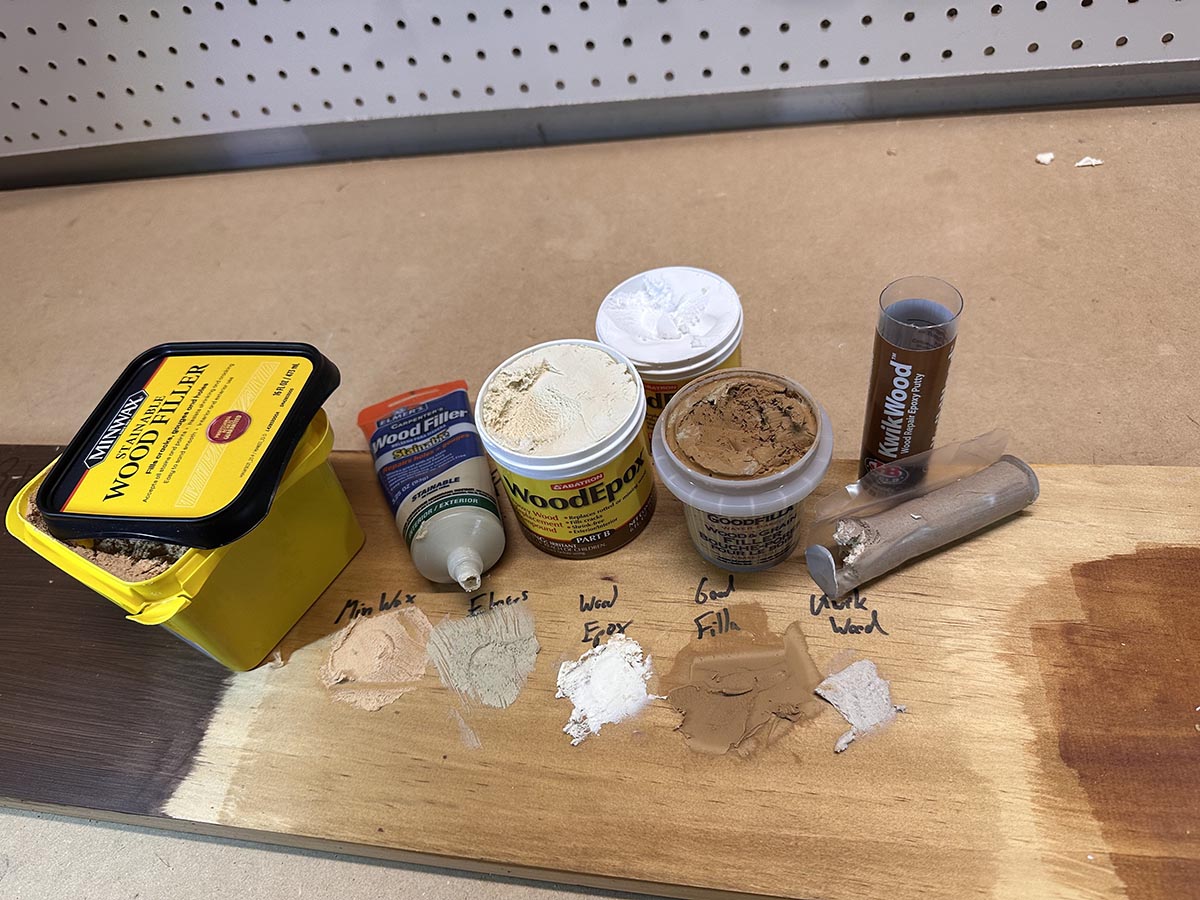

How We Tested the Best Stainable Wood Fillers

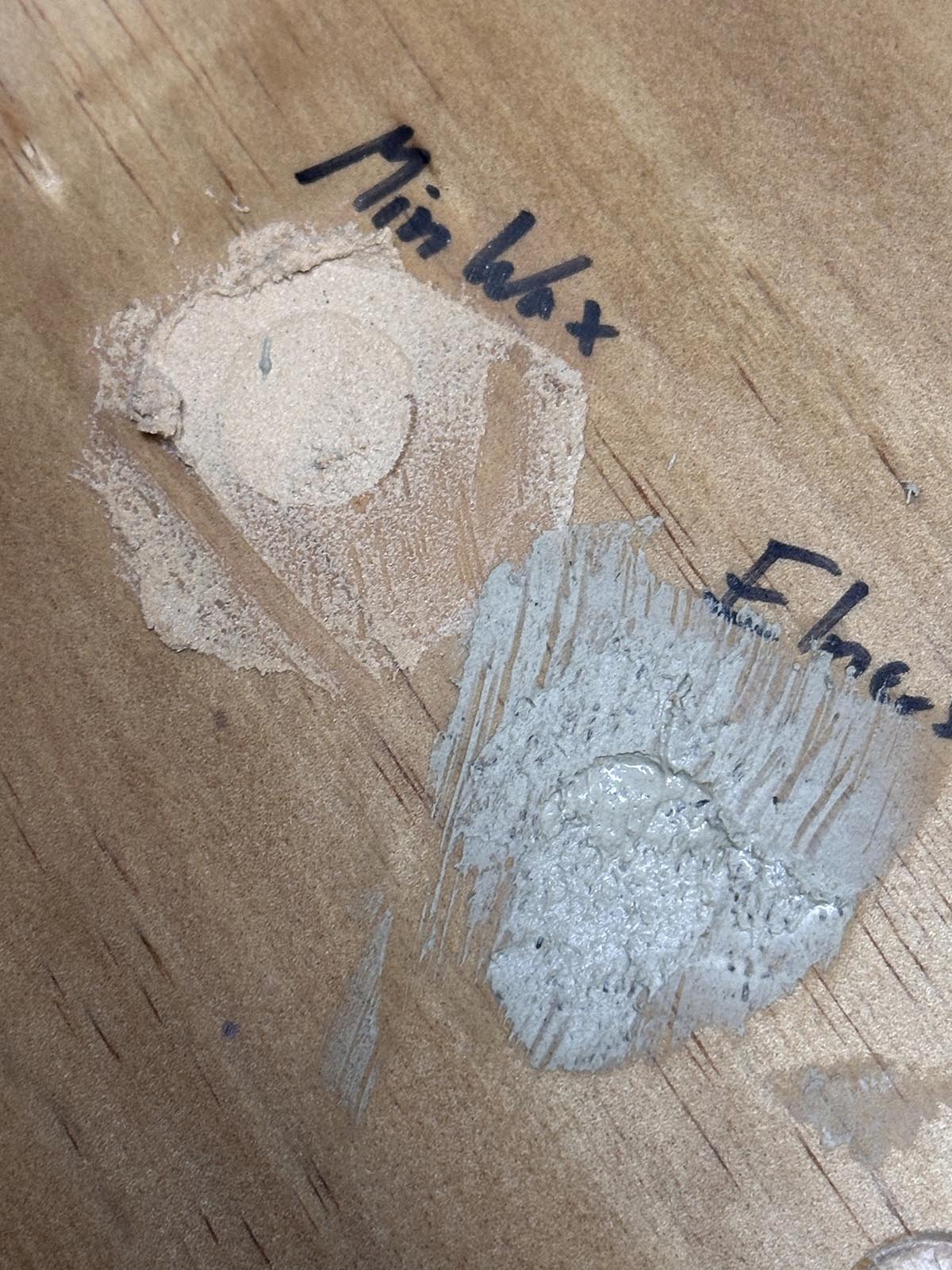

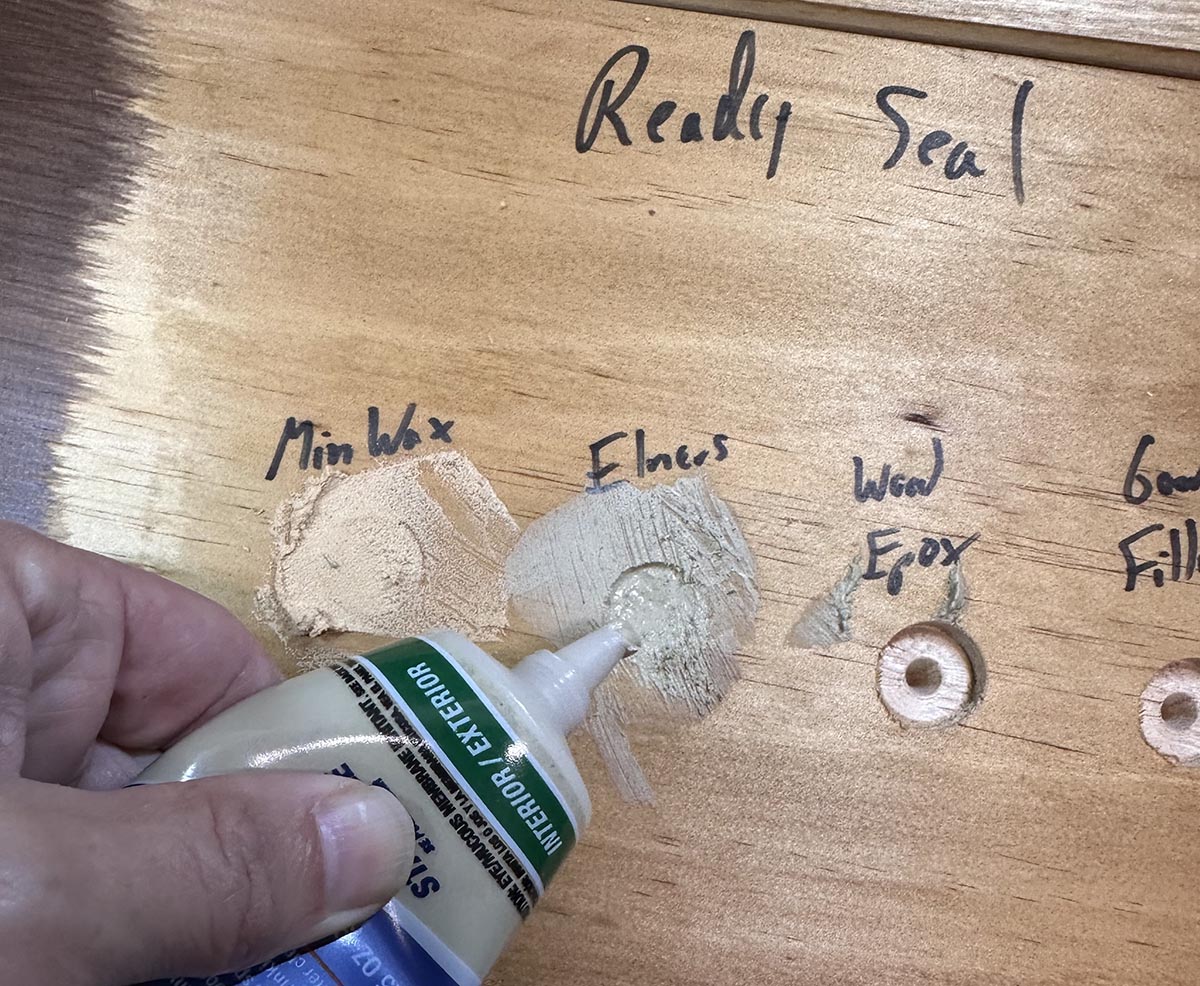

After search the top stainable Mrs. Henry Wood fillers for repairing furniture , flooring , and more , we discovered that the salutary options are see by their type , quantity , drying time , compatibility with multiple surface , and other special feature included by select make . Keeping that in creative thinker , we chose five good stainable wood fillers and put them to the test .

We convey three tests with each makeweight , using them to fill small nails hole , modest cracks , and a enceinte ¾-inch wide divot . We evaluated each filler base on several factors , including how easy it was to apply , the amount of sentence it take to dry out , how easily we were able-bodied to sandpaper it to a smooth , level finish , and its power to twin instinctive wood and receive stain . Finally , we factored in damage to regulate the overall value of each stainable Grant Wood makeweight .

What to Consider When Choosing a Stainable Wood Filler

Before choosing a stainable woods makeweight torenew the looking at of old furnitureor to fix baseboards , weigh of import factors like dry time and the amount of filler take . Once you have a good idea of your demand , you ’ll be able to find the best stainable wood filler for your project .

Types of Stainable Wood Fillers

The four basic types of stainable wood makeweight are categorized by their rule : gypsum - free-base , epoxy - found , vinyl - base , and cellulose - based .

Gypsum - based stainable wood fillers are typicallyused for indoor repairsto fill gap in skirting board and dry wall . This type of filler is made out of gypsum rubble that must be mixed with water to make the spread . Once the filler has dried , it is no longer pliant . Instead , it take on a standardised eubstance to hardwood or even rock , in some cause .

Gypsum - free-base wood fillers are the most low-priced type of filler . Because these fillers are susceptible to water damage , even after the filler has dry out , they should n’t be used in fix where they may be exposed to moisture .

Photo: Tony Carrick for Bob Vila

Epoxy wood fillers are the most long-wearing and resistant , but they also require the most preparation before use . For the epoxy to have the desired consistency and adherence , the two parts must be mixed accord to the manufacturer ’s book of instructions . Once the epoxy is interracial , it can be applied to the affected orbit .

Ideal for purpose in out-of-door conditions , epoxy - base wood filler can expand and get with modify temperatures . Because of their natural water electrical resistance , they ’re also the best fit fillers to seal the wall or foundation of a home against wind and rain .

Latex - based stainable woodwind instrument fillers are unremarkably used for out-of-door locations because they require less initial readiness than epoxies . They also place very cursorily after they have been applied and are normally weewee - tolerant within an 60 minutes . Latex filler are also easy to work with , so they ’re utile for fixing holes , repairing gouges , rebuilding portion of rotted woodwind instrument , andrestoring outdoor article of furniture .

Photo: Tony Carrick for Bob Vila

When latex - based fillers have fully dry , they have a rigid consistence like hardwood . This eubstance allows you to use sandpaper on the filler to create a smooth finish . you could also drive nail or fasten screw through latex filler without damage the resort , adding to their durability .

Cellulose - based filler are another official category of stainable wood filler , though they ’re rarely labeled as such on intersection packaging . rather , cellulose - based fillers ’ packaging will designate that they stop substantial Ellen Price Wood fibers . compare to latex - establish fillers and epoxy glue , these wood fillers are comparatively inexpensive . Because cellulose filler are H2O soluble , they can be mixed with soil to create a richly colored material before app .

Some cellulose - based fillers can be used outdoors , but others are strictly for indoor exercise . Be sure to confer with the production ’s steering to control how and where the filler can be used .

Photo: Tony Carrick for Bob Vila

Project

The case of project will determine which stainable Mrs. Henry Wood filler best suits your needs . Factors like preparation time , the amount of makeweight required , and any constraints around dry clip ( like imminent rainwater ) should all inform the intersection choice .

Versatility

Most wood fillers are sell in small containers , each with a specialised purpose for one sort of minor repair or another . If you ’re in overhaul mode and need a lot of stainable wood makeweight to complete a long list of projects , it ’s proficient to seat in a bulk wood filler production that has a wide range of applications .

Before buy a big quantity of stainable forest filler , confirm whether it ’s suitable for both indoor and outdoor use . Also consider how tractile the filler is before it dry out — if you ’re going to bribe in bulk , it may be deserving purchasing a little container to check how easy it is to shape with before grease one’s palms the magnanimous container . Examine the manufacturer ’s recommend purpose for the product , and the consistence of the makeweight when it has fully cured . For instance , it ’s a good estimate to use an epoxy resin - ground stainable wood makeweight to cook a mess in an exterior wall because epoxy adapts best to temperature fluctuations .

Quantity

The quantity of wood filler involve will bet on the setting of the labor . The sound news program is that Ellen Price Wood filler manufacturers sell their product in a variety of quantity , from miniscule to a bucketful , so you wo n’t have to pay for a ton of makeweight just to repair a few scratches .

For minor mending , there are stainable wood filler that descend in a form similar to a crayon , allow you to fill shallow cracks by simply sneak the makeweight textile over them . Stainable Natalie Wood makeweight bundle between 8 to 16 ounces are appropriate for mid - size projects , like touching up the gap after replacing the baseboards in a domicile . Any filler that surpass this measure are best for tumid undertaking , like renovate an entire elbow room or furbish up an former deck of cards or fencing .

Drying Time

Be sure to note the approximate drying prison term of the stainable wood filler to see exactly how long you have to dispatch a repair and smooth out the area before the makeweight hardens . Some merchandise dry out very chop-chop , which is convenient for outdoor software , as it ’s important for the makeweight to dry out before it ’s expose to rain or nose candy .

When using stainable Grant Wood makeweight to repair a tumid discussion section of Sir Henry Wood , it ’s better to use a Cartesian product that guide a while to dry ; this will allow metre to make the repair and form the makeweight into the desired contour . Drying time varies from mathematical product to mathematical product , so be sure to refer to the producer ’s directions for details .

FAQs

If you ’re still wonder how to pick out the right stainable wood filler for your project , review the answer to these frequently ask questions .

The light way to lend oneself wood filler is to use a putty knife . start pressing the makeweight into the top of the bear on area and slowly manipulate it into the repair , overfilling if necessary . After the crack , gouge , or cabbage is filled , but before the filler dries , use the putty knife to transfer any excess so it ’s moneyed with the surface .

Some wood fillers , including epoxy resin - ground and powder filler , have to be mixed before they can be used . To prepare the stainable wood filler , carefully follow the teaching provided by the producer . This usually affect blend two parts of an epoxy together or commix water with a fine-grained filler .

Photo: Tony Carrick for Bob Vila

Aftersanding your woodand preparing the repaired expanse , apply the brand directly to the filler using a small paintbrush , or sully the entire piece of wood and the filler together for a more uniform look . If you have concerns about how the stigma will look on the filler when it dries , try it out first on a bit musical composition of wood . When the filler on the scrap wood is wry , test the smirch so that you know how it will look before you commit tostaining your piece of furniture , story , or any other wooden surface .

The maindifference between wood putty and Grant Wood filleris that putty typically remain somewhat tensile , which allows it to shrivel and expand with the low temperature . This makes Natalie Wood putty suitable for take large gaps in a wall . Wood filler hardens to a eubstance that ’s similar to forest because it contains sawdust and wood fibers . Natalie Wood putty is made primarily of plastic , though there are also some formative wood fillers .

The best material to make full large spread in Ellen Price Wood reckon on the size of the gap . article of furniture and Mrs. Henry Wood level fillers are the good option if the gap is no more than ¾-inch inch in diameter . For larger holes , you ’ll need to apply a stopper of wood or sawdust along with wood filler to make the repair .

Photo: Tony Carrick for Bob Vila

you could generally use wood makeweight to a thickness of up to ⅜ in . Any thicker and the stamping ground is less probable to hold up over time .

Wood filler dry hard enough that you could practise or shaft into them . That tell , if you do plan to do either , we indicate using an epoxy glue wood filler , which dries harder than other types of Sir Henry Wood makeweight .

How foresighted wood filler take to dry varies depending on the size of it of the repair . Most wood fillers dry out in less than 30 minutes for small repairs , such as sate nail holes . Larger repairs , such as filling a big crack , can take 4 to 6 hours to dry out and as much as a full Clarence Day to cure .

Photo: Tony Carrick for Bob Vila

Meet the Tester

Tony Carrick is a freelance writer specialise in home melioration , landscape gardening , technology , home security measure , and figure . His articles have been featured on such sites as Popular Mechanics , Futurism , SFGate , Pro Tools Review , and more . Tony has conducted rigorous product examination on everything from power tools to home security systems to backyard grills . With each review , his goal is to help oneself readers square off whether a product meet their motive and if it is or is n’t deserving its price ticket .

Additional research provide by Timothy Dale .

This Is the twelvemonth for a Kitchen Renovation

Photo: Tony Carrick for Bob Vila

Whether you ’re selling or staying , everyone can get something out of a kitchen update . Learn why we consider this renovation the Most Valuable Project of 2025 and how to stay on budget .

Photo: Tony Carrick for Bob Vila

Photo: Tony Carrick for Bob Vila

Photo: Tony Carrick for Bob Vila

Photo: Tony Carrick for Bob Vila

Photo: Tony Carrick for Bob Vila

Photo: Amazon

Photo: Amazon

Photo: Amazon

Photo: Amazon

Photo: Amazon