We may clear tax revenue from the product useable on this pageboy and participate in affiliate programs . Learn More ›

One of the biggest innovations in the living accommodations market has been theintroduction of 3D - printed homes , which constructor can create faster and more affordably than those made with stock construction practice . Thus far , three-D - print homes have primarily been made from concrete , but a party calledAzureis fructify to change the game by offering a more eco - friendly selection .

According to theEnvironmental Protection Agency , the construction and demolition industry sends more than 145 million tons of wastefulness to landfills every twelvemonth . Concretemakes up 85 percent of that waste matter .

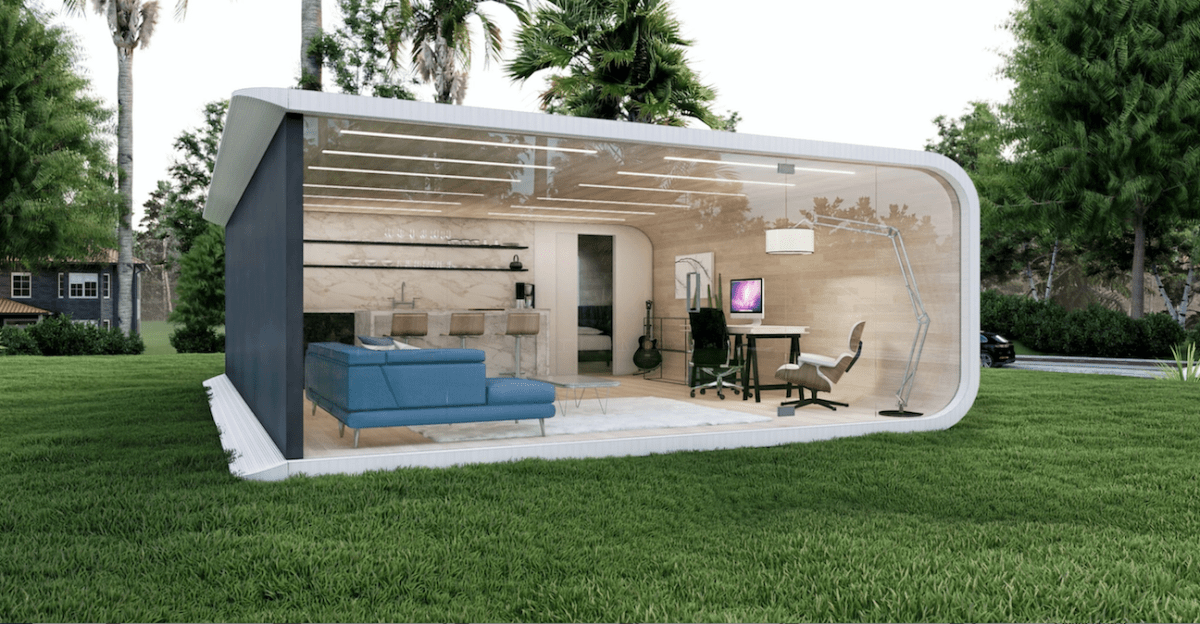

Photo: Azure

Rather than using concrete , Azure usesrecycled plastic to craft its structure . In fact , more than 60 percentage of the materials that make up Azure homes amount from recycled plastic that is used in water bottle and solid food publicity . Until now , Azure has only make small backyard structures , but the companionship ’s next move is to offer full - sized dwelling house from this eco - friendly process .

How are these structures made?

sky-blue launch in 2019 because cobalt - founders Ross Maguire and Gene Eidelman had a vision of creating domicile more promptly , affordably , and sustainably . They recognize that the construction diligence was ill-famed for going over budget and not staying on schedule , and dream of offering an choice . Not to mention , the construction sphere is the “ largest globular consumer of raw material globally ” and is “ responsible for roughly 20 percent of the world ’s full carbon emissions,”according to the blade .

Azure recently open a 15,000 - square foot factory in California to house its usage - made 3D printer , which will finally produce household that the company can ship across the country . Clients will work with Azure to customise the innovation of their social system , and select thematerials , color , and other point they need .

Once the design is complete , printing will take only 24 time of day . Because the process is so quick , Azure purport to deliver end products much more quickly than those made using traditional grammatical construction practices . Azure estimates that its 3D - printed homes are 20 to 30 percent cheaper than homes made from standard building materials and can be complete 70 percent quicker .

Photo:Azure

How much do the 3D-printed structures cost?

Azure is presently offering pre - orders for two kinds of structures : backyard studiosandaccessory dwelling unit , or ADUs . The backyard studios measure 120 straight invertebrate foot and therefore do n’t require building permit in most municipalities across the U.S. Prices start at $ 23,900 and vary bet on buyers ’ design specification . These small space can be used as family offices , gyms , plot rooms , creative person studios , and more .

The ADUs are bombastic , measuring 450 square feet or more . monetary value start up at $ 99,900 for these more wide structure , which can be used asguest houses or income units .

Each structure is preassembled in Azure ’s California mill and installed by Azure ’s squad upon delivery . It takes approximately three day to link up the body structure tolocal usefulness like body of water and electricity , meaning these 3D - publish unit can be up and running in trivial time .

If you ’re considering buy a 3D - print structure from Azure , they are presently available to pre - order of magnitude for delivery on or after July 1 , 2022 .

Everything You call for for a Lush and Healthy Lawn

go along your gage gullible and your plant thriving does n’t just take a dark-green pollex — it starts with the right tools and supplies .