We may clear revenue from the products useable on this varlet and participate in affiliate political program . Learn More ›

Flattening board faces and squaring their edges is a necessary process at the beginning of woodworking projects , but does everyone really need a long plane ? Using a tool for this step corrects cupping and warp in the woodwind , making it leisurely to fit the workpiece together for glue or fixing . For one - off projects , a combination ofjointing aeroplane , powerfulness planer , router , and/or board sawing machine can do the chore ; After all , baron jointer plane are big and expensive . On the other hand , frequent ( or even periodic ) use may justify the purchase of a power jointer to make the body of work more efficient . Benchtop jointing plane have sure limitation that I ’ll discuss in this review , but they are an intriguing choice for woodworkers who build small projection in small shops . I tested theRikon 8 - in Helical Style Benchtop Jointerto find out how it would perform in that kind of place setting .

Rikon 20-800HSP 8-Inch Benchtop Jointer: At a Glance

Our valuation : 4.5/5

Top Pick

Rikon 20-800HSP 8-Inch Benchtop Jointer

Testing the Rikon 20-800HSP 8-Inch Benchtop Jointer

Massachusetts - found Rikon Power Tools Inc. design and engineerswoodworking toolsand equipment in the US and manufactures in its ISO9001 - licence manufacturing plant in Qingdao , China . Rikon peter savor a favourable repute for initial quality , preciseness , and strength among serious hobbyists and small - scale professionals .

TheRikon 20 - 800HSP 8 - in Benchtop Jointerfeatures a helical dash cutter head , a 90 - degree to 135 - degree tiltable fencing , and an extendable table with a maximal total length of 51½ column inch . A 10 - amp electric motor turn the cutter at a rate of 20,000 revolutions per minute ( RPM ) . The cutter head is equipped with 16 carbide insert that have 2 disregard edge — when the initial edge gets nicked or becomes dulled , simply go around to the wise side for lengthened vesture .

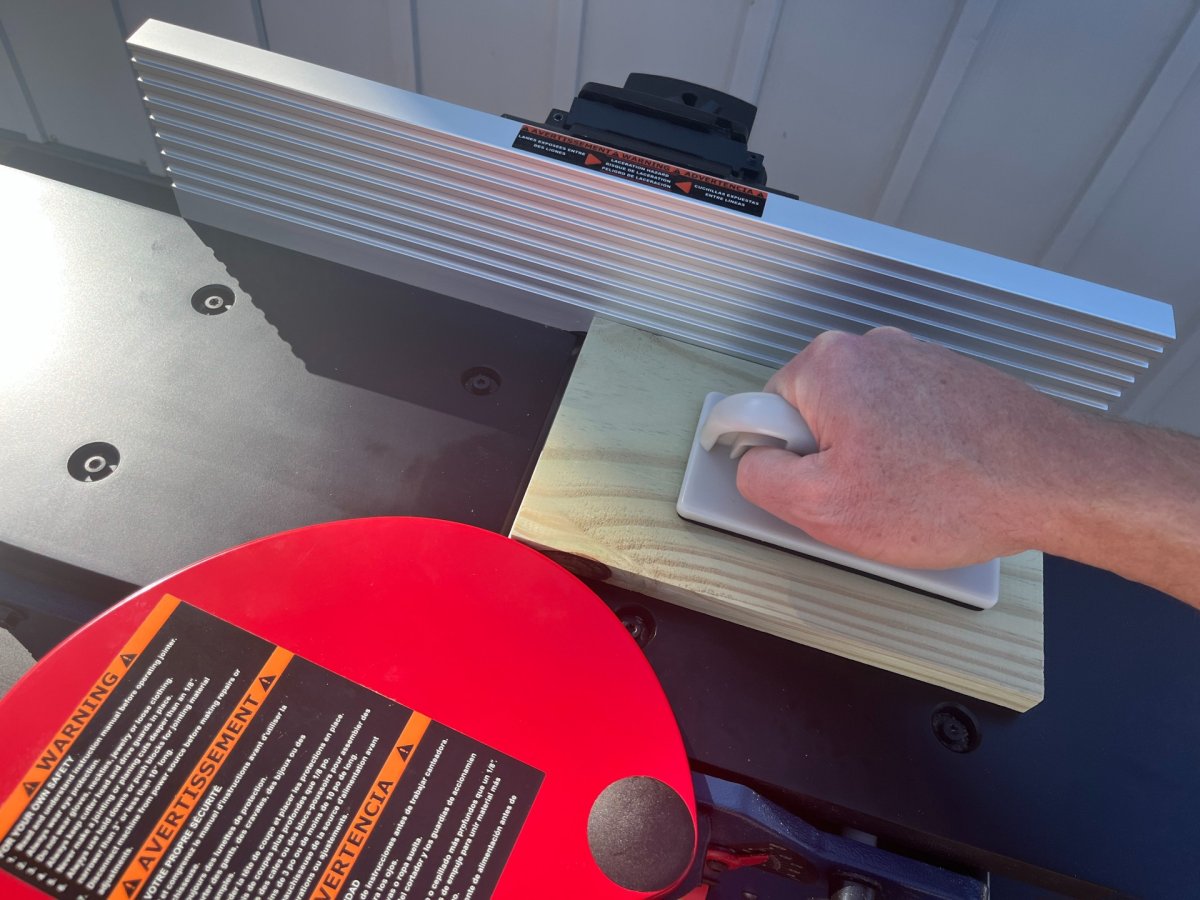

Over four months , I spent close to 30 hours prove the Rikon 8 - inch Jointer in my small shop . I have used it for the traditional use of flatten out and squaring storage - bought lumber , and for a like step in the process of milling circuit board from logs . Most of the boards I litigate are less than 6 inch wide and 3 foot foresighted . For those projects , this motorcar worked perfectly . I have also advertise the limits with longer , wide board . I based my positive rating on my middling use pattern because I believe that is the intended utilization pattern of the dick .

Photo: Mark Wolfe for Bob Vila

A Purpose-Built Tool for Small Woodworking Projects

The Rikon 8 - inch Jointer lead from 30½ in to 51½ column inch long and measures 18¾ inches wide and 13 inches high . It is a commodious size of it to set up on a work bench . At 49 pounds , it ’s light enough to move in and out of memory board but heavy enough to fend movement during cognitive process — whether mounted or relying on the non - skid substructure . The 8 - inch clipping breadth allows generous capacitance for side jointing , which micturate this machine suitable for a wide variety of woodworking task .

One notable detail about the cutter head is that the 16 carbide inserts are not genuinely “ whorled . ” The edge are positioned square to the cut , but the cutters are arranged in a “ helical ” form around the mind . That being said , I was systematically pleased with the smoothness of the results . Another likely egress is that the fencing has a small amount of flex under press . In three months I only had to readapt to square up once , but it ’s something that users will need to supervise , especially when doing a lot of boundary piece of work .

Since I am in the habit of crosscutting workpieces to length prior to flattening them , and I did n’t already have a traditional jointer plane , the comparatively short bread and butter bed on theRikon Jointermade no difference of opinion to me . With the extension bars pulled out , I had no problem processing boards up to 6 feet recollective , but there was a arrest . The ends of longer warped or arciform boards would sometimes fall away into the void between the extension bars after slip by the cross piece of the extension . As an prosperous and effective mess , I pose combat of ⅛-inch plywood to bridge the extension bars and keep the boards flush with the table .

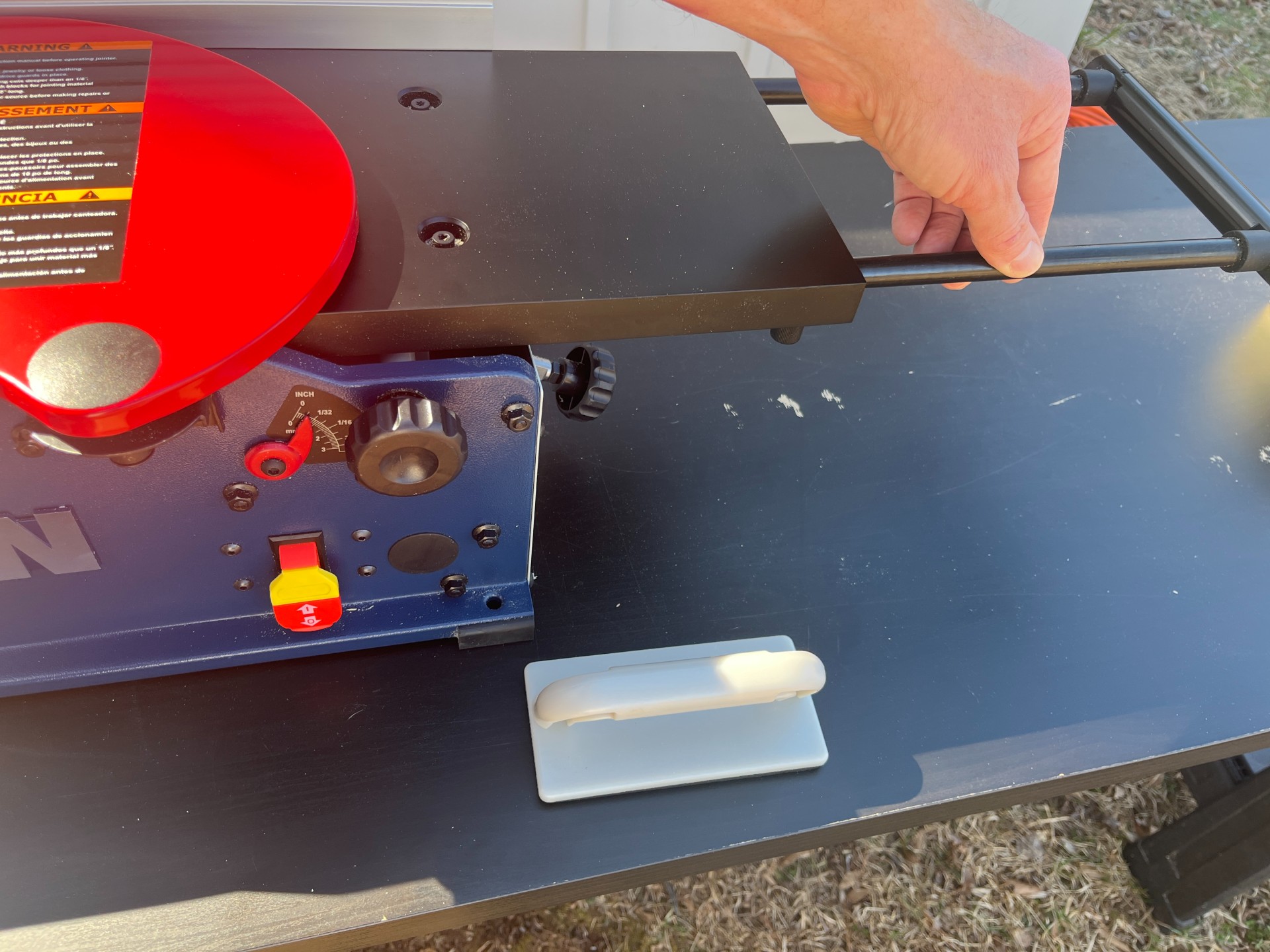

Photo: Mark Wolfe for Bob Vila

Easy to Set Up and Adjust, No Special Wiring Required

Several key features hike up the Rikon benchtop jointer ’s convenience ingredient . First , the power cord is a standard 110 - volt . Many freestanding jointers postulate a 220 - volt outlet , which is fine if the store is wired for it . I appreciated the flexibility of this 110 - V benchtop social unit . I could plug it into any way out in my workshop , author , or distant project situation without worrying about plug compatibility .

The Rikon also features convenient , simple modification organisation . This setup could not have been easier in terminus of operate adjustment . The fencing backing arrangement is equipped with lock lever for quick , secure location change . The tool includes a horizontal positioning adaptation and a tilt modification with positive stops at 90 degrees for square corners , and 135 degrees for making 45 - degree edge bevels . After initial setup and calibration , which conduct less than two minute , set remained true throughout the testing period .

As with any press cutting machine , blade criminal maintenance is a vital feature — and any automobile with fidgety , unstable blades can be dangerous or will sit idle in the shop class . The depth of the cut is one important thoughtfulness . On this jointer , the pinnace head location remains constant , while the infeed table is lift or lowered to correct the cut depth . Right out of the box , I used a straight edge and followed the standardization procedures outline in the manual of arms to ensure that the tables and cutter head were properly aligned — they were . Going forrader , the only necessary adjustment was to raise or lower the infeed tabular array , depending on the amount of material I needed to take per laissez passer . Unless the board was hard cup or extremely rough , I kept it at less than ⅛ column inch . The cutter head on this motorcar is equipped with a set of 16 carbide square inserts that are acute on two edge . This design eliminates sharpen as would be required with traditional jointer knives . In this case , tocopherol the insert edge that is square to the fabric provender direction does the clipping , leaving the second sharpness in reserve . When the first sharpness becomes muffled or damage , I can move out one screw and turn out the insert 90 degrees to activate the second edge . When that one becomes dull or damage , I will replace it . Since carbide is much tough than traditional blade sword , I expect to get about twice the output from these insert compare to the time between sharpening brand long plane knives . After 30 hours , I have not had to rotate the insert .

Photo: Mark Wolfe for Bob Vila

Cuts Surprisingly Fast, Leaves an Excellent Finish

I am a hobbyist who sometimes needs to drop warped boards or make boards from logs for small projects , and this machine has done exactly what I needed . It is forte , so I ensure to wear out good pinna protection while I sour , but it does not seem to be any louder than my DW735 planing machine . Most of the workpiece that I flow it are 6 inches wide or less , and I usually dispatch between 1/32 inch and 1/16 inch at a sentence . In this scenario , the Rikon 20 - 800HSP processes all types of wood quickly without bogging down and produces a flat , smooth open . I seldom change the fence , so its ability to remain faithfully square is more valuable to me than adjustability . I made a few adjustments as part of the examination process , and it created near - double-dyed 45 - degree bevels each time I try on it .

I regain the table annex to be most helpful whenever I work with board that are longer than 24 inches . Since I started using plywood to end the gap between the extension streak , I store those piece of music together with the jointer and instal them right off as part of my setup function . They eliminated what , in my opinion , was the only real rickety point of this tool at no extra monetary value since I made them from scraps that were lie around the shop .

The only remaining issue that diminished store proprietor might not be prepared for is detritus / chip assemblage . The Rikon benchtop jointerdoes have a vacuum port beneath the outfeed table , but it does not actively “ blow ” the debris out . Without a dust collection system or vacuum , it will become clogged with debris fairly quickly . I normally use my besotted / dry vacuity for this determination and it does a seemly job , but it does lend a machine to the available power supply .

Photo: Mark Wolfe for Bob Vila

A Fair Price for Better Than Average Performance

Selling for $ 699.99 , the Rikon 20 - 800HSP benchtop jointer is priced slenderly higher than comparable role model from other manufacturers . Popular theoretical account from Grizzly , Wen , and Wahuda range between $ 400 and $ 550 . All of these long plane have similar cutter heads and table designs , 10 - amp motor , and extendible table . Two key differences are the type of insert used and the cutting focal ratio — Rikon ’s cutter head runs 40 to 50 percent faster than the contender . Some of the others use high - speeding brand ( HSS ) instead of the more indestructible carbide cutters on the Rikon unit . This was also the light - weight 8 - inch jointer we explore , weighing in at 49 pound sign . Altogether I think it ’s a fair Mary Leontyne Price for a dependable performer .

Buy the Rikon 8 - Inch Benchtop Jointer on :

Product Comparisons

So, is the Rikon 8-Inch Benchtop Jointer Right For You?

The Rikon 20 - 800HSP 8 - Inch Benchtop Jointer is not for everyone . It ’s a forte tool at a significant cost point that plenty of woodsman do without , either by purchase bounty wood or by finding creative workarounds using tools they already have . Those who determine to buy a long plane , where space allows , typically opt big freestanding good example that can handle big workpiece . All of that being said , there are plenty of small scale of measurement hobbyist like me who have serious distance limitations or simply stick with diminished project . We are the butt market for benchtop simulation like this one .

For those who are considering a benchtop jointer instead of a bombastic freestanding tool , this one may be ideal . It is fairly lightweight but not tenuous . It was well-off to fix up and adapt , and consistently produce accurate flat face and square edges . It may not be the cheapest of its sort , but it volunteer good economic value for the price .

Meet the Tester

Mark Wolfe is a writer , production quizzer and serial DIYer who lives in an older home . When he is n’t writing , he spends his time upgrading , repairing , and replacing anything and everything in his household , yard , and garden . He tests and writes review about hand and powerfulness tools , lawn care and home repair products , and outdoor bread and butter goods .

Everything You call for for a Lush and Healthy Lawn

Keeping your grass greenish and your plants boom does n’t just take a green quarter round — it starts with the right tool and supplies .